Other Parts Discussed in Thread: BQ76930

Hi team,

My customer is evaluating BQ769X0 in their project.

Below are some questions, could you please help to give some comments? Thank you.

1. Why did cell 10 and cell 15 of BQ769X0 read data on the evaluation software that was 5mV lower than the actually measured voltage, and others cell voltage are normal?

2.Why does the Coulomb counter with BQ769X0 be enabled with more power consumption than the Coulomb counter with disabled?

3. Before and after the BQ76930 package is heated by the customer’s soldering iron, the measurement of cell voltage varies significantly.

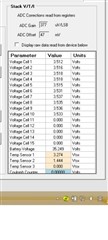

Before heating

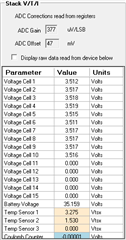

After heating

Appreciate your help!

Thank you.

Regards.

Ivy