Hi team,

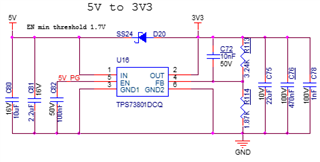

TPS73801DCQ here C72=10nF.

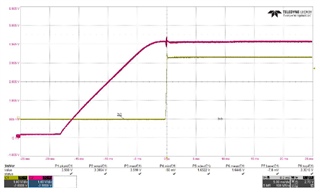

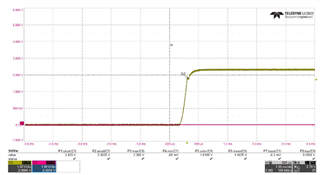

Then the 3.3V curve shows like below,there is a overshoot (3.6V maxium)

If i change the value of C72, when C72=100nF, overshoot will reach 4V maxium (3.3Vtyp).

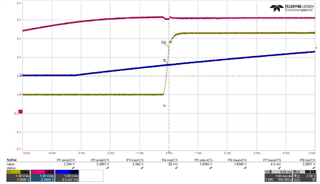

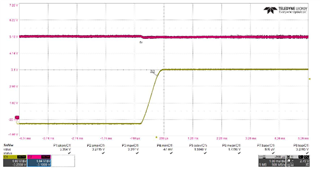

I change the value of C72, when C72=33nF, overshoot will become to a ditch .

So i am confused about how this happen. Maybe the power on load of TPS73801DCQ is too large?

I change the value of the output capictor c75,but there is no significant use.

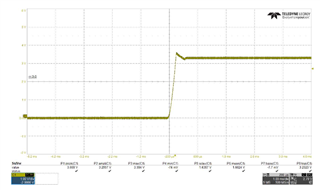

So i change the ic to TPS73701, then there is a good startup curve.

1、I want to know how can i debug TPS73801DCQ, then i can get a satisfied startup curve?

2、What is difference between TPS73801MDCQPSEP and TPS73801DCQ? Can TPS73801MDCQPSEP improve?