Other Parts Discussed in Thread: BQ76952, BQSTUDIO, TIDA-010208

Hello,

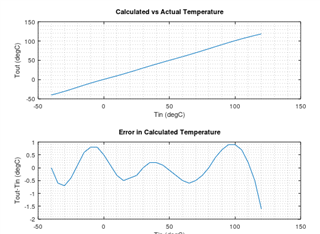

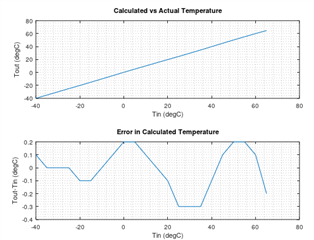

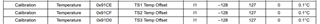

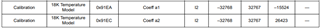

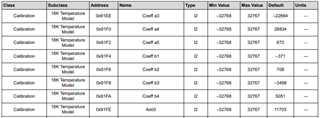

We're attempting to use the internal temperature protection on the BQ76942 protection IC. The A and B coefficients were configured using the excel spreadsheet provided in the technical documentation for this chip. The issue we're having is that the reported temperature does not perform well at reasonably low and very high temperatures. The temperature is objectively verified using a separate well calibrated digital temperature module.

We've configured the internal pullup to 18kR, and the nominal resistance of the thermistor is 10kR at 25 degrees Celsius. We've tried using both the 18kR internal model, as well as the custom temperature model, both perform virtually identically. The Adc0 was empirically verified, and the Rc0 was selected using the defined formula in the reference manual of the BQ76942. In ice water (about 4 degrees Celsius), the thermistor model returns 17 degrees Celsius, and in hot water (80 degrees Celsius) the thermistor model reports 84. The model does seem to perform well within the range of 20 to 70 degrees.

Any insight into how we could improve the performance of the temperature model would be much appreciated!

Thanks,

-Alex