Other Parts Discussed in Thread: PMP21529,

hi,

I'm making 4 switch buck-boost converter using UCD3138A. I did analyze the reference design PMP21529 and I saw that it's hard switching between topologies (buck, boost, buck-boost) using interrupts (standard_interrupt.c) measuring input/output voltage. My question is is there an easier way to do this, using UCD3138A HW only, without any ARM supervision?

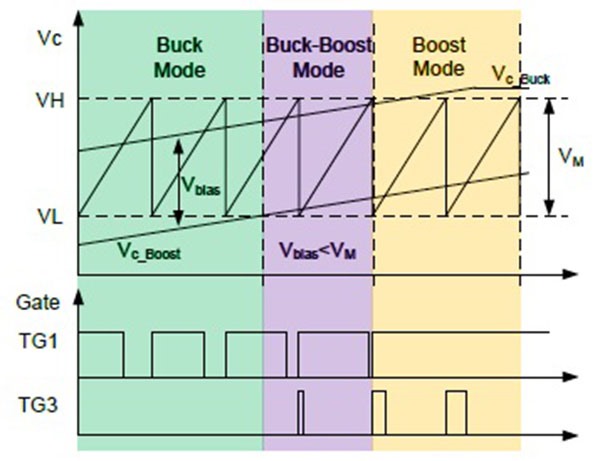

It could be done using this approach (even better with triangular mode) but it would then require adding bias to filter output, which I think, is not possible.