Hello Team,

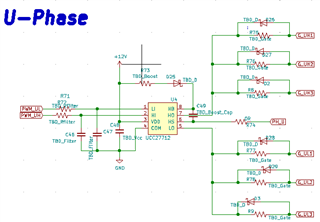

We have come to the Ti part UCC27712dr for Our motor Control application

Want to verify few things Before we procced to design

1)Gate driver capability to Drive the Mosfet's(3 in parallel)

2)Boostrap Diode Voltage rating

3) You recommend to use Zener diode at LO & HO Pin

System Parameter

System Voltage :60V

Vgs: 12V

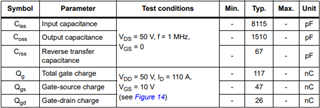

MOSFET Parameters attached the Image

No of MOSFET Parallel:3

targeting Raise time:500ns

Fsw:20khz

PFA of mosfet Data

And gate Driver Schematic

Thanks