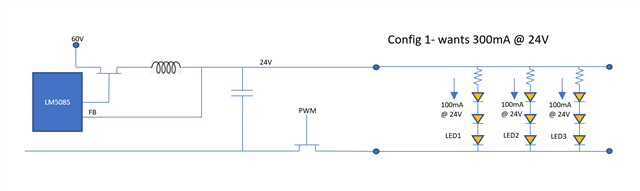

Other Parts Discussed in Thread: TPS92518, LM5085

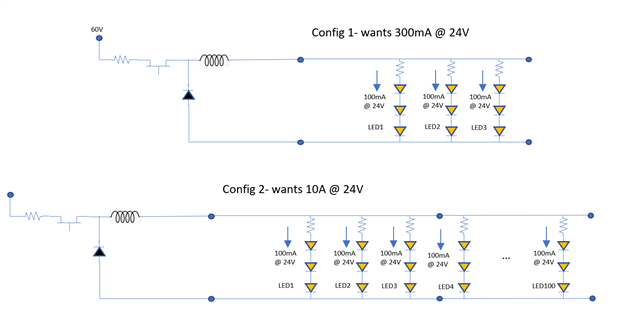

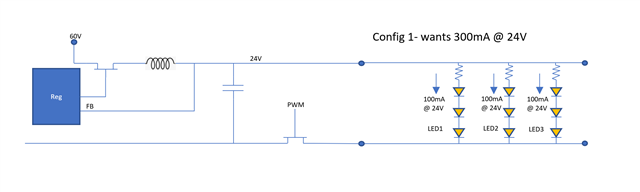

Hello- I am looking for candidate devices for LED drivers for diving light strips. The number of strips can be variable adding more 24V strings of LEDs in parallel up to a 10A total current draw.

PWM dimming at a visually undetectable frequency is required.

Input voltage is up to 60V

Is the TPS92518HV a good candidate to use?

Can the device be set so that if there is one set of LEDs that only needs, say 100mA, the voltage is still at 24V. Same if there are 1000 sets requiring a collective 10A?

Can the two outputs of this device be combined in parallel to achieve the 10A requirement?

Thanks!