Hi,

I am designing a PSFB converter for a POL application (20-40V to 1.3V/60A) and I would like to use the UCC28951 with a current doubler rectifier on the secondary side.

I am currently calculating the transformer parameters. I got a turn ratio of 5 and I have chosen the shim inductor to achieve ZVS above 50% max load current (which is 60 A) as indicated in the datasheet.

My question is about the magnetizing inductance that I want as low as possible for transformer volume considerations.

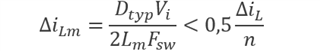

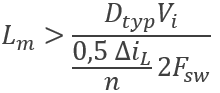

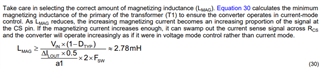

The datasheet explains (page 42) that if the magnetizing current is too high the controller can lose current mode control. It then gives an equation to calculate the min value (see attached image).

I would like to know :

1) why is the controller losing control in case of high mag current ;

2) where does the equation come from (as I need to adapt it to the current doubler rectifier) ;

3) As the equation uses the typical duty cycle (not the min), is it really a minimum value ?

Thanks in advance !

Téo