Other Parts Discussed in Thread: TPS7A84A, TPS61027

Hi TI Support,

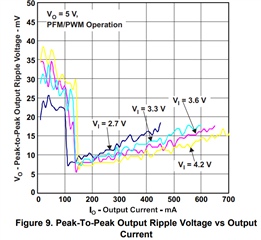

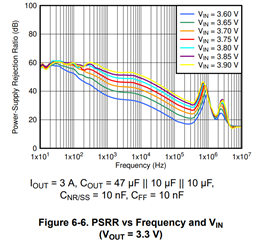

We are considering the TPS81256 for an Bluetooth audio application, but are concerned about the PFM feature generating noise within the 20kHz audible range, as well as the increased ripple associated with this mode of operation.

Our power source is a single-cell Li-Ion battery, 5V output of the TPS81256 will be fed into a 3.3V LDO regulator to power all internal circuits. Our circuit presents a dynamic load of between 10mA to 40mA @ 3.3V.

After carefully reviewing the data sheet, we can't find information on the transition point between PFM and PWM operation; it is only stated that PFM operation is used under light loads.

Any advice of information you can provide us will be greatly appreciated.

With best regards,

Claudio