Hi Team,

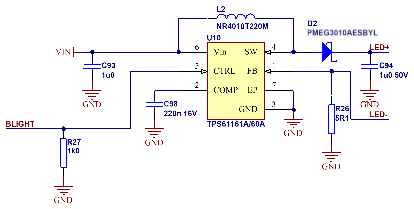

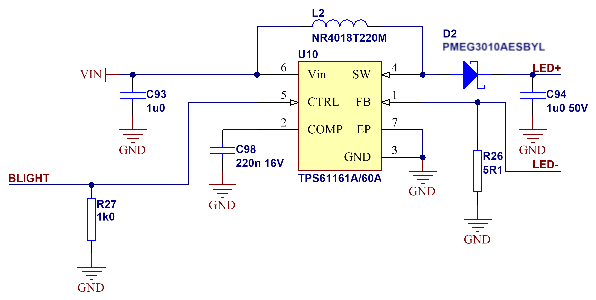

The circuit is the same as shown on the datasheet except Rset is 5R1 (current at 40mA). The CTRL pin is connected to the micro and has a 10k pull down resistor.

The issue is that sometimes after a powered up reset from say, an Over the Air update, the TPS61160 stops working, let’s say locks up as there is no recover from it other than a full power cycle.

My question is what can we possibly be doing during the “warm” reset that could be locking up the TPS61160? The power supply to the TPS61160 is not removed, the only thing is that during the “warm” uPC reset, over which we have no control, that the CTRL pin does something odd which upsets the TPS61160.

Any ideas? Thanks.