Other Parts Discussed in Thread: TPS54160A

Hi TI Expert

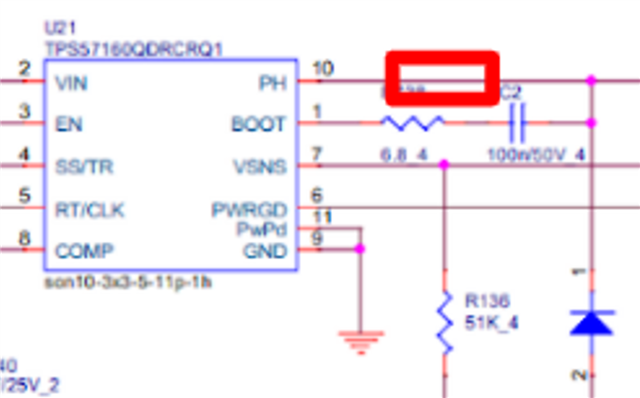

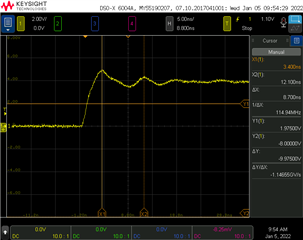

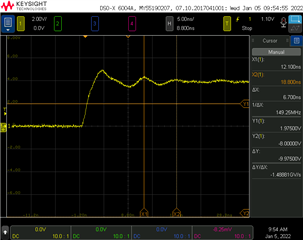

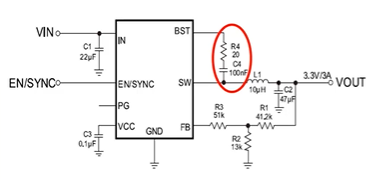

due to RF desense issue, our customer would like add a bead on PH pin, here need TI help to check does it affect any functionality issue? what impact to add it bead on PH pin in view of TI?

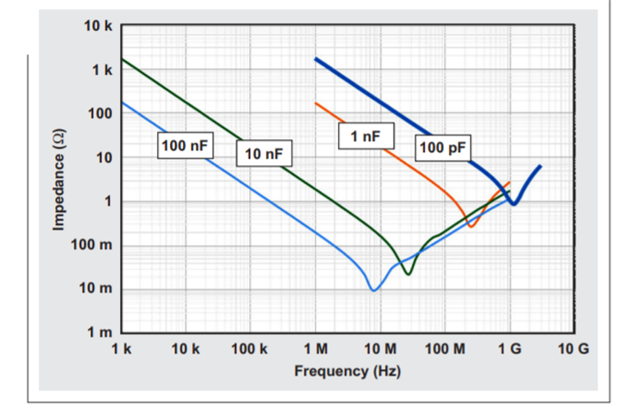

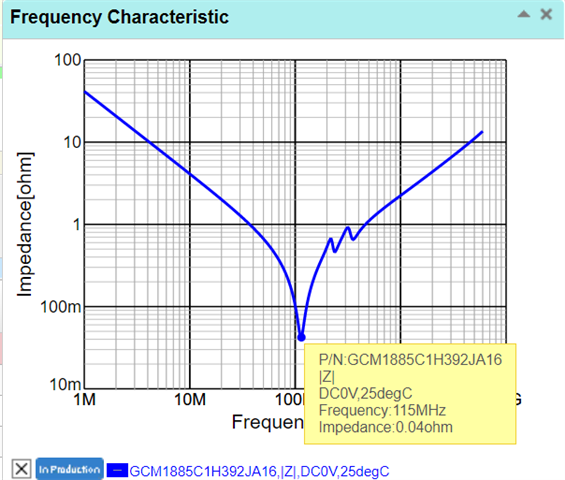

Bead PN : muRata BLM15EX331SN1.

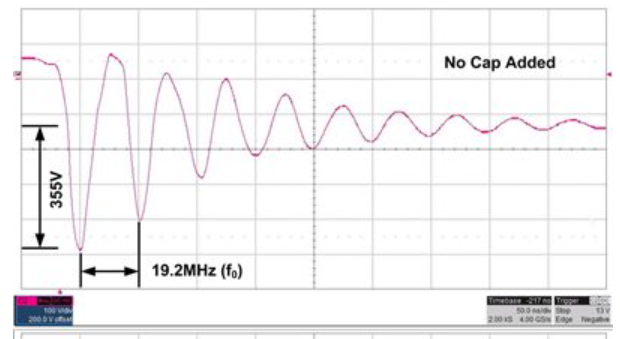

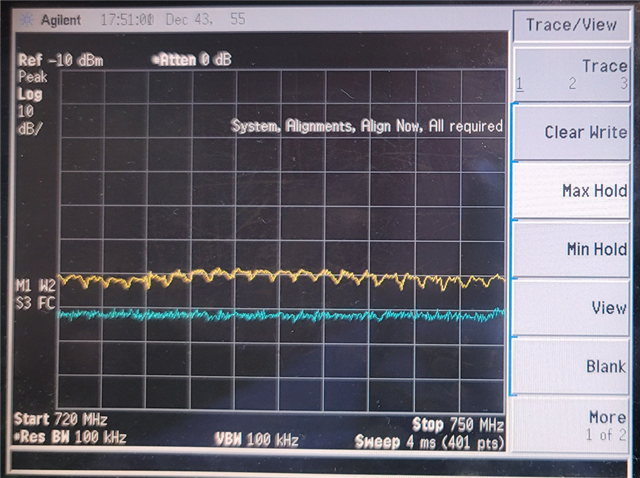

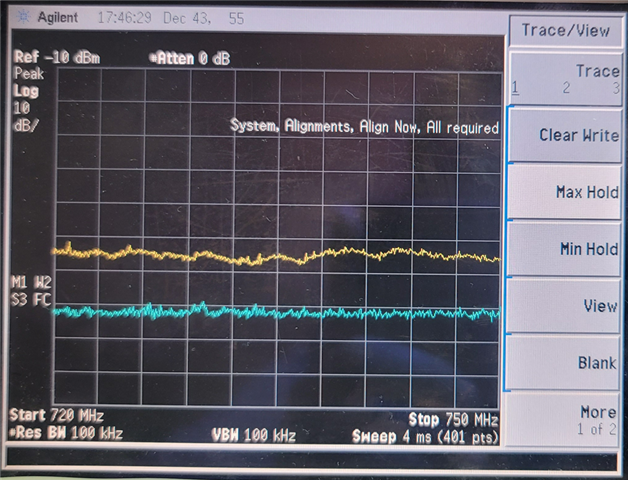

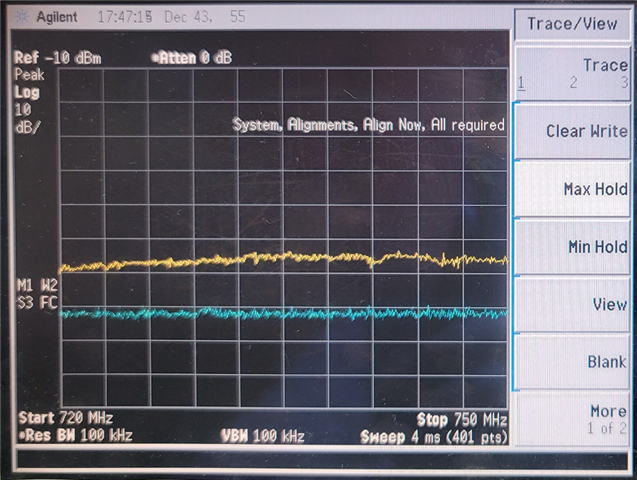

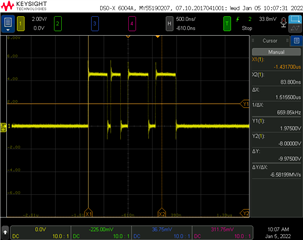

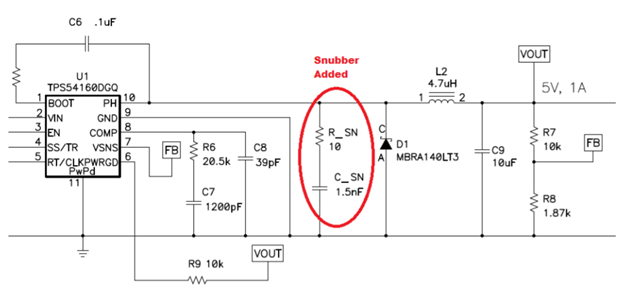

BTW, does there any other suggestion to improve the desense performance? since our customer ask why this DC converter are super-duper noisy when they use near field probe can see the noise comes from on TPS57160Q. (LTE B12 700MHz)