Hi team,

Here's an issue from the customer may need your help:

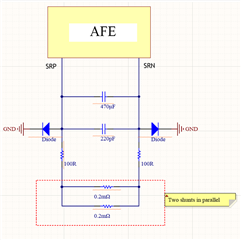

Customer-designed acquisition board for the BQ76952, after some time of I2C communication, the chip will pull down the SDA, resulting in an I2C communication interruption.

VG=43V when control of precharge MOS is on and VG=45v when is off. Why is VGS=-8v(total voltage 51v) when is on and VGV=0 when is off? The VGS theoretical value should be -6V at shutdown, why is the precharge MOS shutdown gate different for ground voltage, but the VGS=0.

Could you help check this case? Thanks.

Best Regards,

Cherry