Other Parts Discussed in Thread: BQ25708

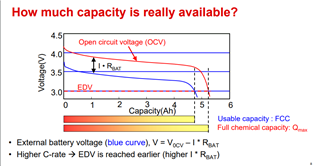

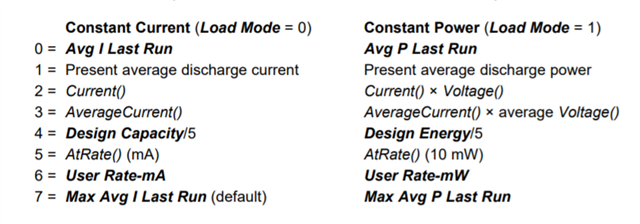

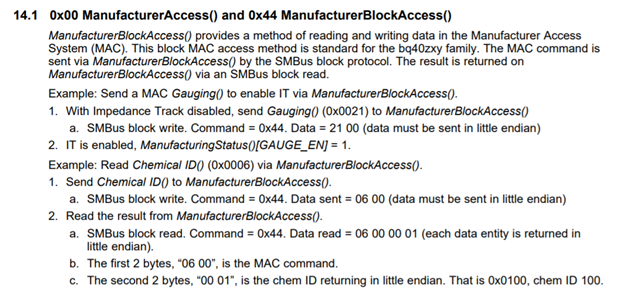

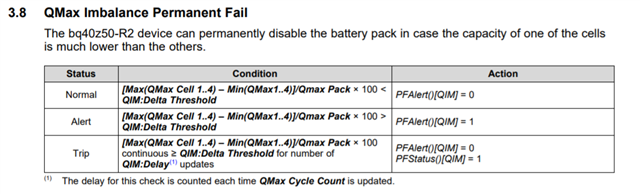

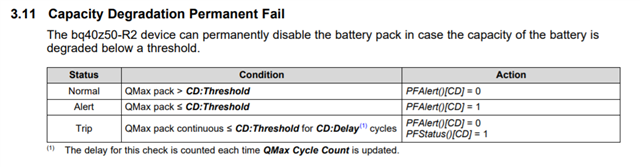

we are using your controller to control lithium battery under 1P4S configuration. i would like to learn what kind of parameter your controller ( BQ40Z50-R2 ) can monitor and register for tracking the battery pack capacity or some parameter which can equivalent to predict battery capacity ?

if you only track the charge/discharge cycle count, can you track the partial charge/discharge cycle for an equivalent damage/degradation ?

do you have an application or best engineering practice for tracking battery capacity ( or equivalent parameter ) ?

thanks

jason Li

reliability engineer

8184472630