Other Parts Discussed in Thread: TPS61161, TPS92360, , TPS61165

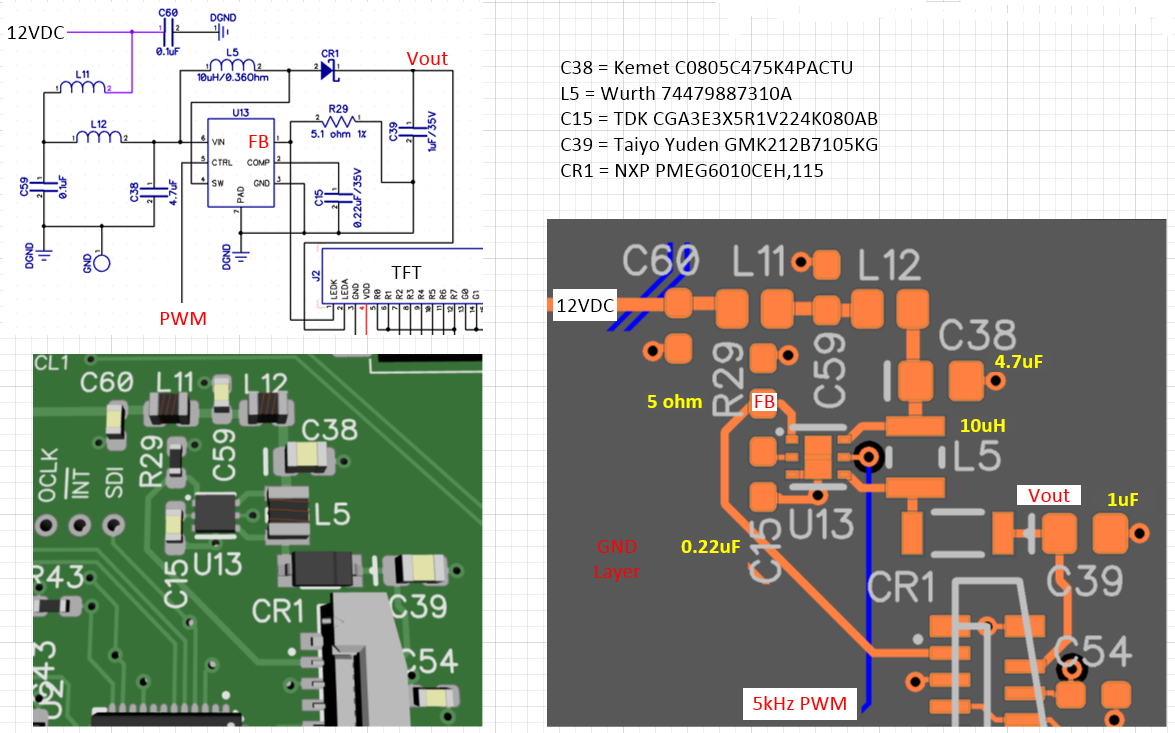

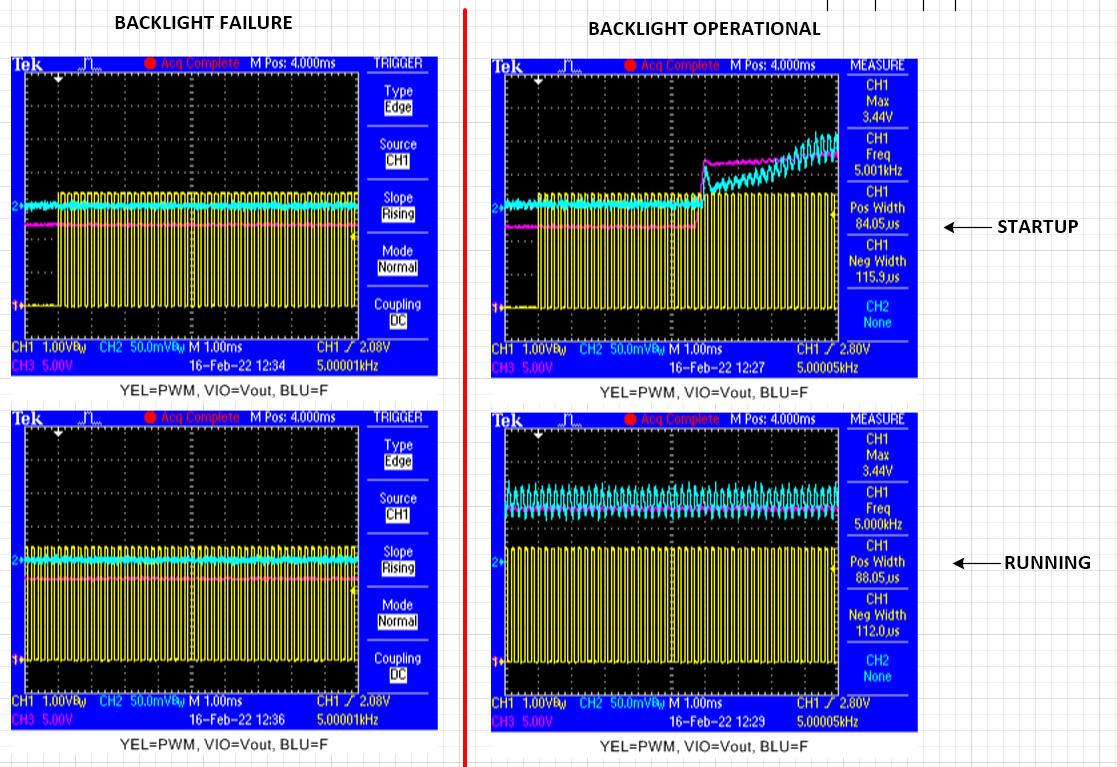

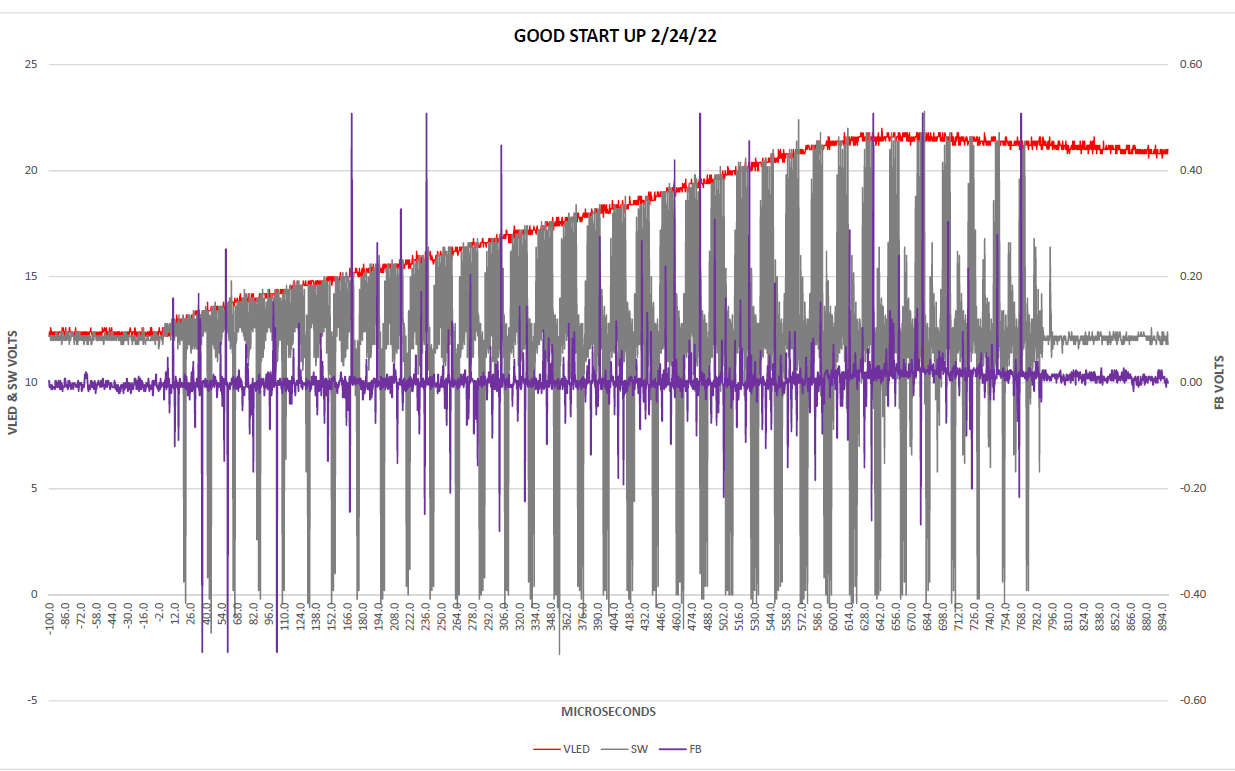

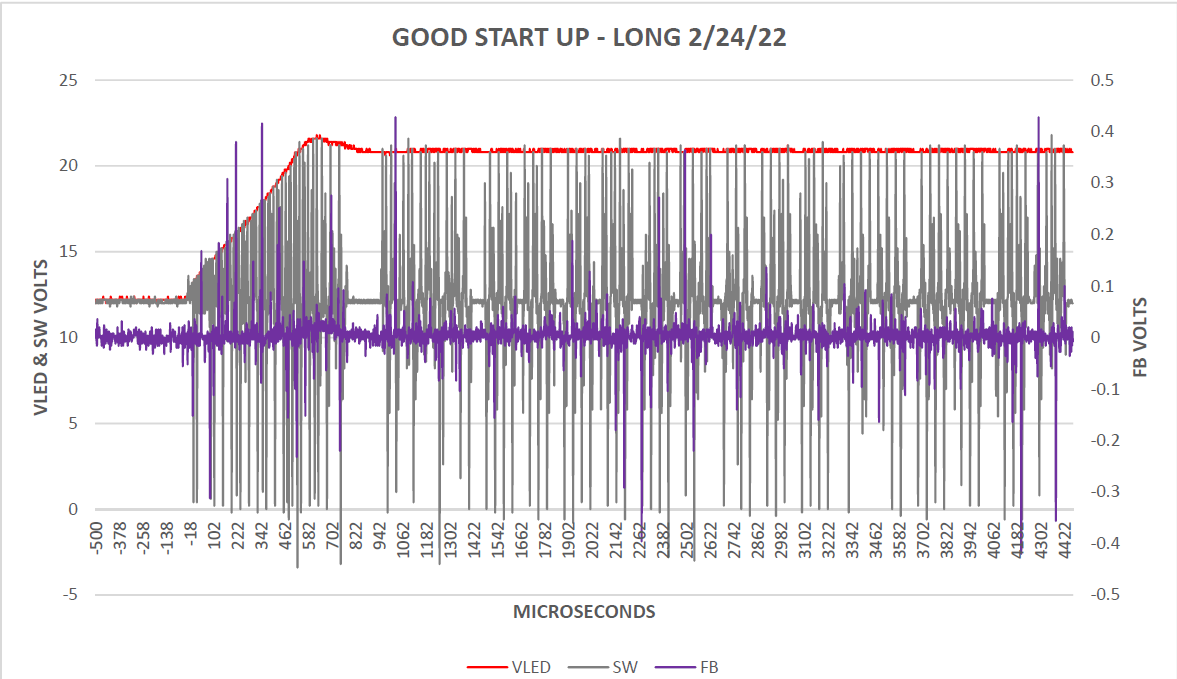

We are using this chip to drive the LED backlight for a TFT display. Initial prototypes worked extremely well, but we have just finished a 40 piece production run where we had 6 failures of this chip. Our next run is 150 units for long term field tests so we need to get this straightened out. I do not believe at all that we had defective parts, based on my test data it looks like we had ESD damage to the FB pin. This seems to have occured either during handling of the boards after reflow or during connection of the LCD display to the connector which is right next to the TPS61160.

What I would like to do is insert a resistor between the cathode of the LED backlight and the FB pin (10 ohms?) and put a transient supressor across the 5 ohm FB resistor to ground. I see that the Vmax on this pin is 3V (same as the COMP pin) I dont think that this will cause any operational issues except for the extra 400mV which will be generated across the 10 ohm resistor. I may also consider an ESD supressor across the COMP capacitor. These are simply right where an operator would place their fingers, we are all ESD gounded but I have no other explanation.

Does anyone see any issues with this, or have experienced anything similiar?

Thanks for any feedback!

Larry Affelt