Other Parts Discussed in Thread: LMR23630, LM2676, LM76003, LM46002, LMR33630, LM22676,

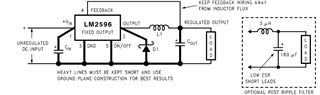

I was planning to use the LM2596S-5.0/NOPB to convert 24V to 5V from a bank supply. I am designing a PCB that will work with 5V and 3.3V.

This card has an MCU32 with an Ethernet interface that processes requests from a host. The uC reads the status of 3 inputs or write to 3 outputs and exchange data it with PC. There is not much more electronics.

This card will be located inside a metal articulated arm that is part of a test bank. This arm is expected that it will be connected to the test system 20-24 hours a day.

I had thought to use this regulator to get 5V. Keeping this in mind:

I was following thedatasheet instructions to select the components and I find that this regulator requires capacitors with VCIN = 35V:50V. If you want to use a CIN = 100uF, the only possible option is to use aluminum electrolytic capacitors. I have observed that the useful life of this type of capacitor for 50V does not exceed 3000h.

The working conditions force a circuit configuration using electrolytic capacitors. But these capacitors cannot offer more than 3 months of service life. So it seems that the circuit may take 3-4 months to show behaviour anomalies or missfunction.

Ceramic capacitors are not recommended, according to the datasheet, because they can produce ringing on Vin. There is no variety of inexpensive tantalum capacitors for 100uF and Vcin >= 35V.

-Can you suggest other capacitors for Cin and Cout in my case?

-Or should I discard this device for these operating conditions?

I would like to add that I don't know which value for Cin using tantalum capacitors will work here instead of Electrolytic. Since the only values that matches:

- Vcin = 2xVin, so 50V,

- highest Irms for ILoads under 1.5A

Are those being less than 16uF. So I don't know if 10uF or 16uF tantalium capacitor will fit here to get best results. Datasheet talks about 680uF for electrolytic capacitors, but it doesn't give any values for tantalum option. I can't achieve more than 15uF with V= 50V. It seems to be a little far from them.

When I say if there is another option I'm refereing to this type of solution in ex: Cin = 15uF, 50V, Irms = 1A, and low ESR smd tantalum capacitor.

But there could be such more.

Thanks in advance.