Other Parts Discussed in Thread: GPCCHEM, BQ24120, BQSTUDIO

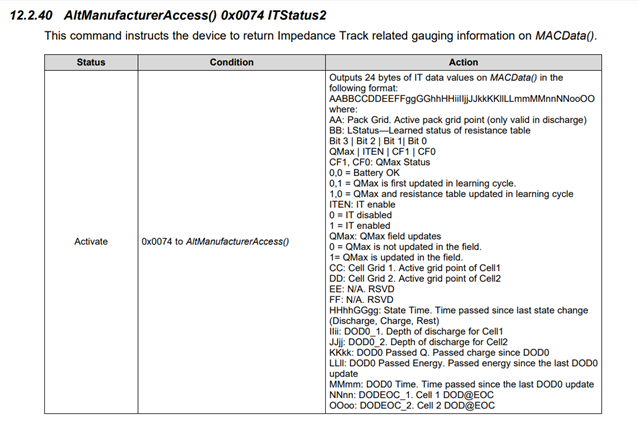

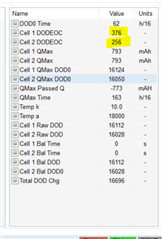

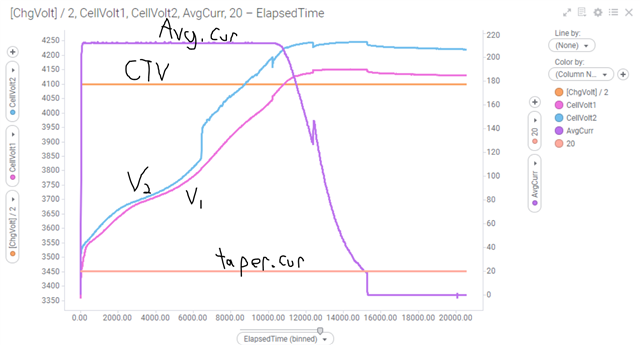

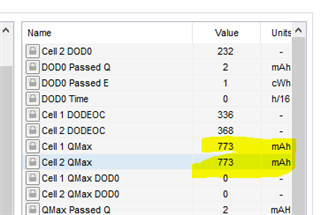

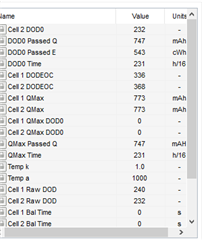

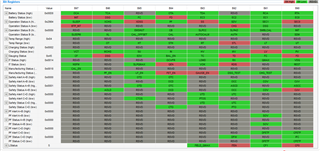

I'm working for learning cycle with a sistem based on 2S li-ion, battery charger BQ28120 with 150mA charging current

- select the chemid with GPCCHEM tool

- program on the EVM : CHEMID, and design parameter as suggested by SLUA 777

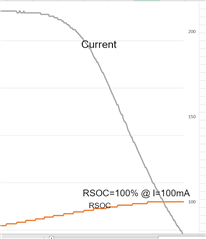

- start discharge, relax, charge relax and so on for learning cycle

I repeat more time the cyces but do not complete the lerning.

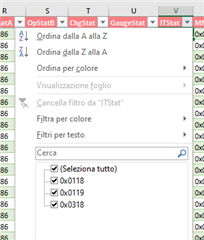

Attached the logfile.2110.charger.zip

may be ITEN ?

may be ITEN ?