Hi everyone,

I have been struggling with the design of a power management module that has among other smps regulators the BQ25300.

I baked the components at 60 deg celsius for 12 hrs just to be sure and used a stencil to apply the solder paste to the pcb an eventually used a hot air gun.

This chip has been the center of my torture after trying the 3rd prototype. It makes me wonder since i have got a xmega16 VQFN, a boost converter and a buck converter and all of them have been working without the slightest instability.

So, after assembling the 3rd prototype, everything worked fine for a few days and then the STAT led started blinking w/o obvious reason. No matter what i did the STAT led would always blink. I noticed that some times the STAT led would stop blinking and the charge current would be the expected value (charging would start). After removing the VIN and retrying, the STAT led would again keep blinking. I tried LiPo batteries at various charge levels with their voltage anywhere between 3.0 and 4.2V. The STAT led would keep blinking.

I checked the conditions that would normally lead to a fault but could not find anything useful.

My VIN has always been 5.0V. The forward voltage drop of the input diode is not a problem since it reaches 400mV @ 2A @ 55 deg which means that a fully charged bat (4.2V) would still be less than the effective VBUS which is 5.0V-0.4V=4.6V

• VVBUS > VVBUS_OVP

• Thermistor cold/hot fault on TS pin

• VBAT > VBAT_OVP

• Safety timer fault

• ICHG pin is open or short to GND

• Die temperature is above TSHUT

This is the schematic designed in KiCAD:

For testing purposes i removed the R3 and connected another R 10-20K from VBUS to EN pin so that the chip is always enabled. POL has been tied to GND, so setting EN to a high logic enables the charging.

The max temperature i detected with a thermal camera was 70 deg celsius for a short period across which the current was almost 2A as set by R5.

The NTC used was the 103AT.

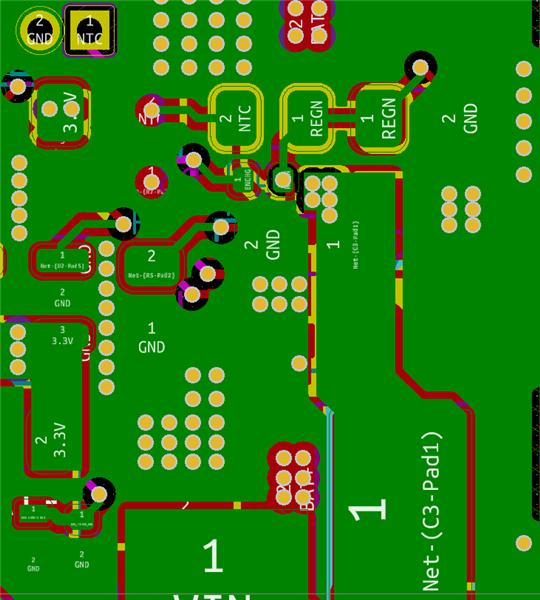

Here are some snapshots of the 6-layer pcb for your reference. I don't expect PCB design analysis off course:

TOP LAYER

INNER LAYER 1

INNER LAYER 2

INNER LAYER 3

INNER LAYER 4

BOTTOM LAYER

I am thinking that the culprit could be any of the following:

- Some decoupling mlcc with the wrong ESR (more or less than required)

- PCB design bad practices E.g: decoupling caps away from a pin etc

- Pop-corning effect having destroyed the die during reflow (i used 300 deg celcius)

- Inherent instability issues from the chip itself (unlikely)

- Some component wrong value

Can anyone please help because i am on deadline here at work and i do not want to use a crappy way of charging the battery since i need to have this ready in less than 10 days.

Regards to all.

Manos Tsachalidis