Other Parts Discussed in Thread: EV2400

Hi,

I'm using BQ27411DRZT-G1A on my custom PCB.

My settings:

DESIGN_CAPACITY = 2200 NOMINAL_VOLTAGE = 3.7 DESIGN_ENERGY = DESIGN_CAPACITY * NOMINAL_VOLTAGE TERMINATE_VOLTAGE = 3000 TAPER_CURRENT = 70 TAPER_RATE = (DESIGN_CAPACITY / (0.1 * TAPER_CURRENT)) QMAX_CELL_0 = DESIGN_CAPACITY

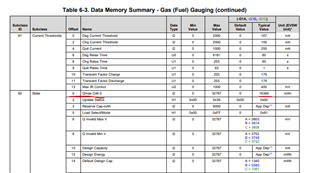

Rest of the Data Memory Configuration is set to typical values (from SLUUAS7B–January 2014–Revised June 2015 datasheet).

Then after exiting cfgupmode and waiting several seconds I read FullAvailableCapacity() (COMMAND CODE = 0x0A) and DesignCapacity() (COMMAND CODE = 0x3C).

Value of Design Capacity is correct - equal to what I set. I expect that Full Available Capacity will have similar value as Design Capacity, but the value is significantly different.

So I decided to test diffrent Design Capacity values. Here is what I get:

| design capacity | full availiable capacity |

| 1000 | 61 |

| 1500 | 136 |

| 2000 | 242 |

| 2100 | 267 |

| 2200 | 292 |

| 2300 | 321 |

| 2400 | 350 |

| 2500 | 378 |

| 2600 | 409 |

| 2800 | 476 |

| 3000 | 545 |

| 5000 | 1514 |

| 6000 | 2181 |

| 9000 | 4906 |

Is this correct behaviour or something is wrong?