Hi All,

I have a question about TPS53513.

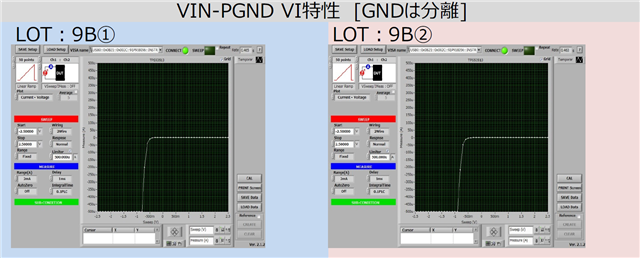

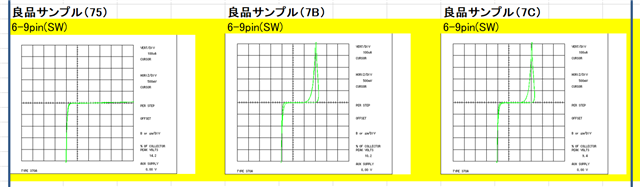

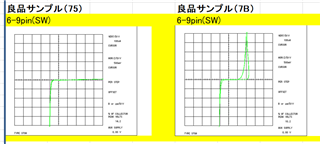

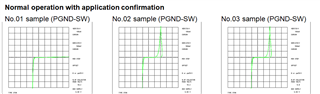

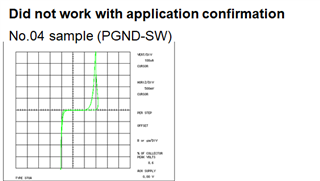

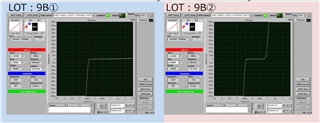

The customer performed an IV evaluation of the SW terminal and the PGND terminal using two samples of good.

The result is as follows.

Results will vary depending on the sample.

Why does it result ?

I think there is a mixture of samples in which PGND and GND are internally separated and samples in common.

Best Regards,

Ishiwata