Other Parts Discussed in Thread: UCC28634

I'm trying to use the webench to design a 120VAC to 24VDC power supply. I must have clicked through at least 25 designs at this point, and all of them seem to share the same transformer topology, and do not use off the shelf parts. Unfortunately, the volumes my customer is looking at do not satisfy the requirements of several custom winders, as we are all still experiencing shortages.

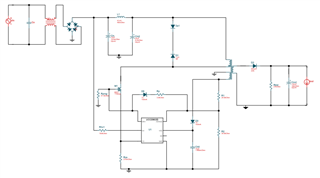

I am working with a webench design based on the UCC28632DR. I'm looking to get a little assistance choosing an off the shelf component that might work, and be able to pass UL certification. I have looked at several, but we don't understand how the webench circuit will supply voltage to the switcher IC without violating UL.