Hello,

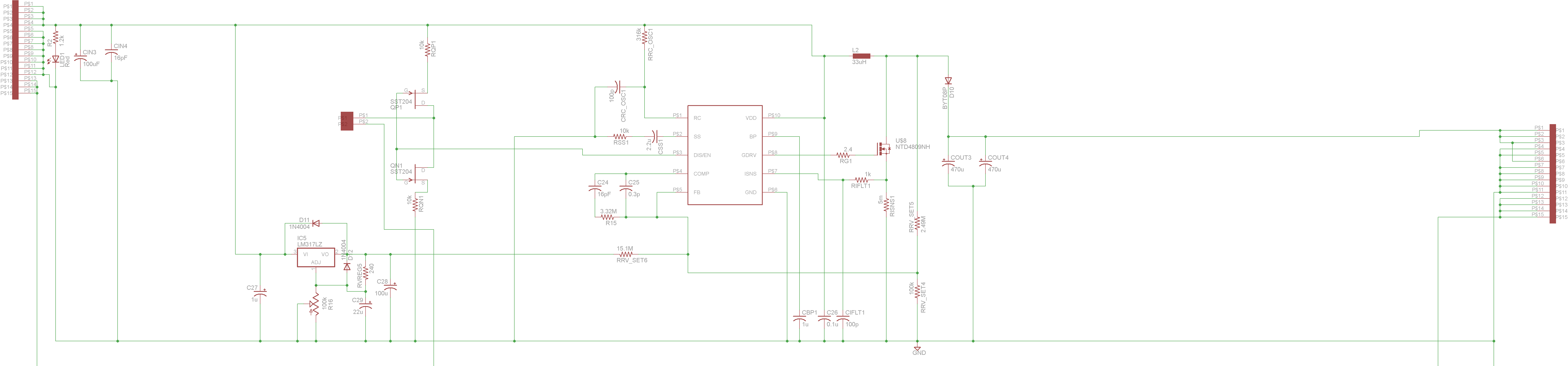

I am trying to design a boost regulator circuit using the tps40210 and am having some problems with the circuit that I constructed. In the datasheet there is some mention that the resistors in the voltage divider network should be chosen with two considerations in mind: low power consumption and noise. Obviously, choosing large valued resistors will decrease power consumption but will large value resistors also make the circuit more vulnerable to noise? I have chosen quite large resistors and am having problems with my circuit. It will switch for awhile when I am measuring the voltage of the FB pin using a multimeter but as soon as I pull the multimeter leads off, the circuit stops switching. Also, the measured voltage at FB is 0.5V instead of the expected 0.7V.

I am attempting to make the output voltage controllable by injecting a regulated voltage at the voltage divider midpoint. I'm not totally sure if this can be done but I've seen it used with other topologies.

Please let me know if the problem I am having is due to large resistor values and if my approach of injecting an adjustable voltage is appropriate.

Thanks for your help,

Neal