Other Parts Discussed in Thread: SFRA

Hello,

I am using LM5170EVM for solar application. My power demand is input voltage 35 V output voltage 40 V and input current 2.2 A boost operation. For MPPT control, I would like to sense current minimum 0.2 A of current from Inductor from IOUT1. The evaluation board is tested with power supply as input voltage and resistor as output load in open loop without analog based outer voltage loop compensator, also channel 1 Enable pin is turned off. The output voltage in the case as said above will be equal to input voltage with diode forward voltage drop. As, the body diode of high side MOSFET conducts, thus with power supply in constant current source.

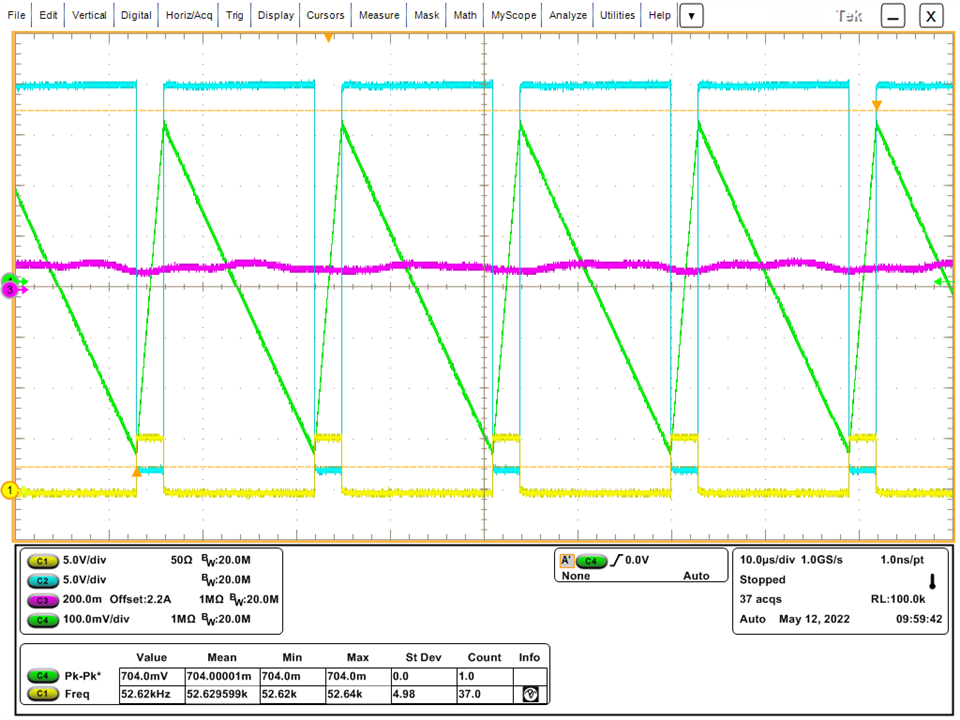

With injecting current in the system, while monitoring IOUT1 in scope:

Under 0 A -> IOUT1 voltage 230 mV

from 0 A to 0.55 A IOUT1 voltage 230 mV

0.6 A IOUT1 voltage 231 mV

0.7 A IOUT1 voltage 235.7 mV

0.8 A IOUT1 voltage 240 mV

Is there any method for measuring/ calculating current between 0 A to 0.55 A?

Thank you