Other Parts Discussed in Thread: TIDA-010080, TPS5431

|

Design Parameters |

|||

|

Parameter |

Min |

Nom |

Max |

|

Vin |

90 V |

230 V |

265 V |

|

Fline |

47 Hz |

50Hz |

63 Hz |

|

Vout |

|

390 V |

|

|

Iout |

|

1,795 A |

|

|

Pout |

|

700 W |

|

|

Vcin_ripple_factor |

|

0,07 |

|

|

Li_in_ripple_factor |

|

0,4 |

|

|

Over Voltage Protection |

|

410 V |

|

|

Undervoltage Protection |

|

370 V |

|

|

PF |

|

0,99 |

|

|

Holdup time |

|

20 ms |

|

|

Fsw |

|

65 kHz |

|

|

Efficiency |

|

0,92 |

|

|

Chip |

UCC28019 |

||

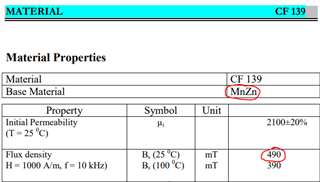

By using the above target parameters, the boost converter topology and the boost pfc circuit were designed. The "sluc069e" calculator was used in the system design. In the system, a 0.6 mH coil with my own winding is used against the minimum boost coil value of 0.311 mH in the calculator (The image of the coil is attached). The EMI filter structure suggested in the UCC28019 datasheet is used at the system entrance. Images are as follows.

The system mentioned above will then feed the LLC Half bridge topology. The whole system is on the same printed circuit board. However, only the PFC circuit will be assembled and the PFC and EMI circuit will be tested and the next stage will be passed.

While testing the EMI and PFC structure, which is the first part of the system, the following situations were realized respectively. No load is connected to the system during testing:

In the first part of the system, the power supply stage given below is fed from the network. A voltage of 14.6 V DC was observed at the output. UCC28019, which is a PFC integrated, will be fed with this voltage.

Next, the “Boost PFC” step shown below was tested. As soon as the system was connected to the mains, the D7, D6 diodes and the road connecting these elements get damaged from the plate. At this stage, the D7 and D6 diodes are taken as an example from the TIDA-010080 reference design.

After this test, no physical error appeared, and D6 diode was canceled because it did not have any effect on the Isense pin other than protection, and D7 diode was also canceled because it had a protection function. However, because we missed it, it was forgotten to connect the R8 pin, which provides the connection to the Isense pin, to the system. In other words, the current information to the integrated is blocked unintentionally. After these corrections, the system was connected to the mains again. It has been observed that fume comes out of the TPS5431 integrated, which feeds the UCC28019.

After the last test, all systems and components were checked for short circuit. As a result of this control, the R8 resistor was jumped with a copper cable and the Isense pin was included in the system by connecting the continuation of R13 with the BR- pin of the C3 capacitor. It was seen that the "VIN" and "ENA" pins of the TPS5431 IC were short-circuited and replaced with a new one. Afterwards, it was observed that the legs of the Q1 MOSFET were short-circuited. It was removed from the circuit and after the internal diode and internal resistance control performed outside, it was determined that it was broken and replaced with a new one. In the continuation of the controls, although a capacitor was connected to the Icomp pin of the UCC28019 IC, it was observed that the pin was short-circuited directly to the ground (GND pin) and it was determined that the UCC28019 was broken and replaced with a new one. After all these changes, short circuit control was made with reference to the design images given above and the system was connected to the network for the third time.

In this test, the mains connection was disconnected with the arc sound coming from the system. In other words, the network connection time of the system is maximum 1 second. In the controls made after this test, it was observed that the Icomp pin of the UCC28019 was short-circuited to GND and the "VIN" and "ENA" pins of the TPS5431 were short-circuited. No physical damage was observed on the elements in the visual inspection made after this test. It has been observed that the control of the Q1 MOSFET is robust. However, the UCC28019 and TPS5431 ICs are damaged.

Questions:

- Could the problems be caused by programming the Vcomp and Icomp pins with wrong values?

- Could the problems occur because the boost coil value is too high than the minimum value?

- Could the problems be caused by the irregularities of the boost coil in my own winding?

- If you think that the problems are caused by the pcb, I can send the design files via DM.

- Other than these possibilities, I have difficulty in estimating the source of the problems. I would be glad if you help.