Other Parts Discussed in Thread: GPCCHEM, BQ76952, BQSTUDIO

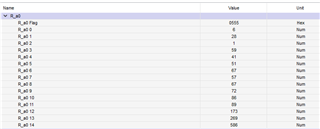

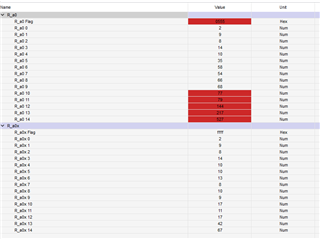

I am currently working on calibrating a 16000mAh 12s pack. I am using a scaling factor of 7 in order to handle higher currents. I have verified the scale factor is correct based on the current measurements.

With an update status of 5, my full charge capacity is only showing 510mAh. When charging and discharging, the remaining % is correct for the time. But using the DC load, I am able to discharge 16385mAh. The state of health is incorrectly showing 22% as well.

Load select = 1 and Load mode = 0

It looks like Design Energy Scale is being applied to the full charge capacity?

Here is my math:

200A Burst Current.

32.76 Amperes Max Reading

32.76A * 7 = 229.32A Max Current Measurement

Scale = 7

16000mAh/7 = 2285.71mAh - Design Capacity

12 * 3.7V * 2285.71mAh = 101485.52mWh

32767mWh max. Use Design Energy Scale of 4.

101485.52mWh / 4 = 25371.38mAh - Design Energy

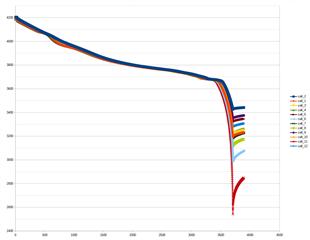

Best chemical ID : 3169 Best chemical ID max. deviation, % : 0.91

Calibrate to 3.3V cutoff voltage