HI

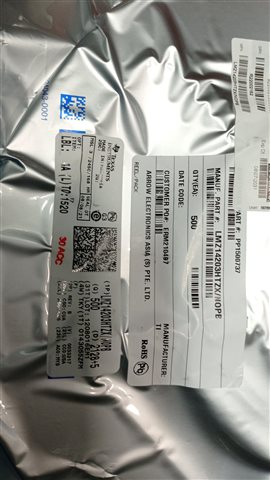

Required recommended PCB land pattern design and reflow profile for part# IC-LMZ14203HTZ/NOPB.

Required below details also

- open via hole on thermal pad of PCB are required or not for IC-LMZ14203HTZ/NOPB ?

- if PCB had tented thermal pad, is it leads to component failure?