Other Parts Discussed in Thread: TPS61094

This inquiry is regarding a suspected-faulty, Texas Instruments (TI) TPS61094EVM-066 evaluation module OR a mistake trying to test this evaluation module - a distinct possibility. This evaluation module enables customers to experiment with different modes of operation of the TI, TPS61094. For our application we intend to use the TPS61094 in the “automatic buck-boost mode”.

We are using a Beagle Bone Black (based on another TI product) single board computer that needs to fully shut down its operating system and MySQL before the power goes away … or bad stuff happens to our database. With a super-capacitor and the specified operation of the TPS61094, we should be able to tolerate random power outages that frequently occur at our industrial clients. Once the AC power goes away, we only need to keep the Beagle Bone Black (BBB) board running for 12 seconds at 5 volts - until the various software systems (especially MySQL) are shutdown gracefully. After the 12 seconds, we are happy to stay quiet without power until the AC power interruption is fixed and 5-volts returns to our BBB.

Our requirements are very straightforward and within the specifications of the TPS 61094. And, the Evaluation Module will be an easy way for us to test this chip in our application. If we could make this Evaluation Module function as specified, we would simply connect our normal 5-volt power supply to the input of the TPS61094 Evaluation Module and the connect the output of this module to the power supply input of our BBB using one of our prototype boards. This should have been a trivially simple test --- but it did not turn-out that way.

Although we are very experienced individuals (BS-EE, MS-EE, PhD-EE from big 10 universities) with a combined total of 50 years of experience, we can still make "stupid/silly" mistakes. Advanced degrees and years of industrial experience are no guarantee against mistakes.

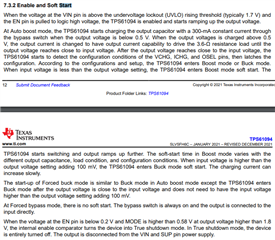

All of our tests resulted in the same electrical response ---- The output voltage precisely tracked the input voltage. That is, the output and input voltage were identical in value. There was no measurable charge (0-volts) on the super-capacitor. The TPS61094 IC may be DoA/broken/damaged but it seems to be operating in a “forced bypass” mode.

There was no measurable 1MHz pulse width modulation frequency at pin #5 (SW)

The “boost” mode failed to operate with the input voltage was decreased below the target output voltage and the “buck” mode failed to operate when the input voltage was raised above the target voltage.

The voltages measured at each of the 12 pins on this device seemed to be reasonable for each different pin. Except pin #5 and #6. There was no 1MHz signal and there was no voltage on the super-capacitor (as noted above).

For our tests, we set the on-board jumpers as follows:

J1 and J5 were used as the Vin+ and Power Supply Ground

J7 (+) and J10(-) were connected to our 35 Farad super-capacitor while respecting the polarity of the super-capacitor.

J11 (Mode) and J12 (EN) were both set to “High” connecting pin1 to pin 2 with the provided jumper block.

J11 and J12 set the chip’s operational mode to automatically Buck or Boost as needed; this is the mode we care about for our application.

J3 (Vout+) and J6 (Vout -) were used to connect the output voltage to a resistive load for initial tests including (30 0hms, 100 ohms, 1M ohm)

JP1 and JP2 were set to short pins 2 and 3. These settings were required to use this device in the super-capacitor mode. This JP1 & JP2 configuration connected our 35 Farad super-capacitor to Pin #6 of the TPS61094 IC and to one side of the L1, 2.2 uH inductor.

JP3 was connected to R6 (13.0 k ohm) so that pin #12 (Vchg) of the TPS61094 would be connected to ground through 13.0 k-ohms. This set the supercapacitor charging voltage limit to 2.7 volts.

JP4 connected R26 (75.0 k-ohms) to pin #11 (Ichg)of the TPS61094 to set the charging current limit to 250 mA.

JP5 connected R45 (274 k-ohms) to pin #1 (OSEL) of the TPS61094 to set the output voltage to 5.2 volts.

For these tests, the load was set to 30 ohms, 100 ohms and 1M ohms. All resistors were separately measured to confirm the resistance values

For these tests, our super-capacitor was a 35 F device rated at 3.0 volts for a fully charged unit without damaging the capacitor. This capacitor was independently tested and charged to 1.5 Volts without issues.

The TPS61094 appears to be “stuck” in a forced bypass mode, even though both EN and MODE lines are set high with on-board jumpers. In addition, I measured the voltage signals going into pin#2 (MODE) and pin #3 (EN). Both values tracked the Vin supply voltage. The output voltage also precisely tracked the input voltage as described for the “forced bypass mode”. During these tests, the Vin supply voltage was varied from 2.9 volts to 5.1 volts.

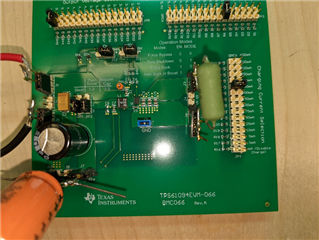

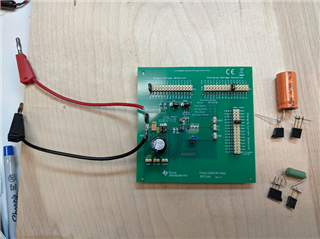

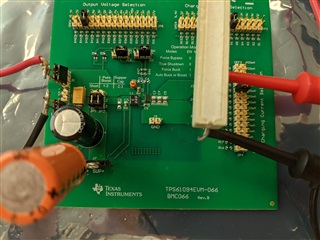

Images Below:

Photos of our copy of the TI TPS61094EVM-066 Evaluation Module with test components – 35 Farad 3.0 volt, super-capacitor and 30 ohm power resistor as a simulated load.