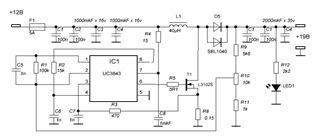

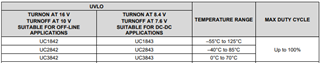

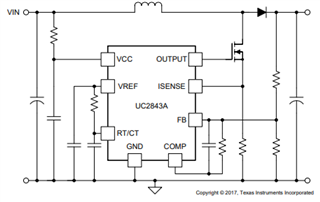

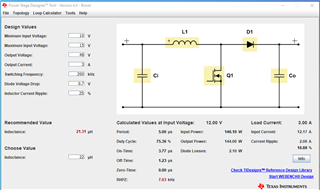

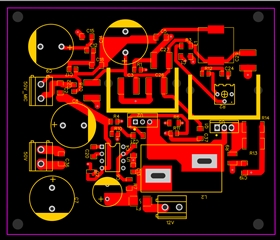

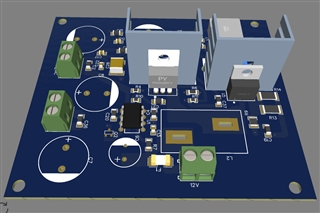

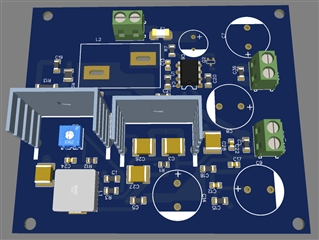

I need a 12-14V to 45-50V battery converter.

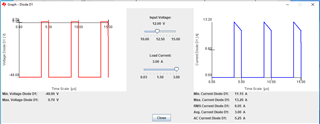

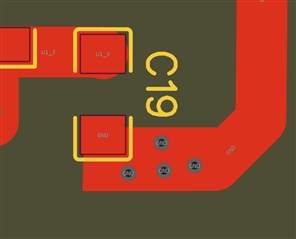

The converter should be adjusting min 45V to max 50V. Power not less than 100 watts. Low voltage ripple. Please advise the chip and circuit for this.

I want to feed a very high quality low frequency amplifier from this unit.

Thank you!