Other Parts Discussed in Thread: TIDA-010208

Hello:

I have a question about bq76952:

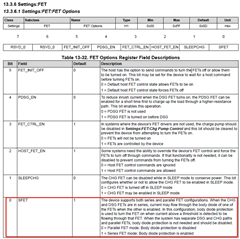

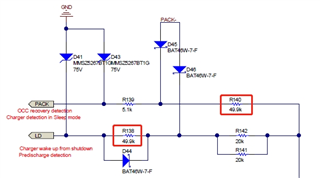

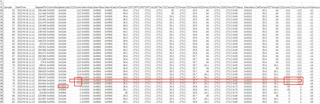

When we use it, the configuration has enabled the SFET bit, that is, the MOS is used in series. Theoretically, when charging, the bq76952 should turn on the discharge MOS, no matter whether there is discharge protection or whether the external MCU controls to turn off the discharge MOS, because it has the "body diode protection" function. The threshold value of the body diode is 50mA. When charging, I can see that CC2 has 101. The user current unit is 10mA, so the threshold value of 50mA should have been met. However, the MOS transistor was not opened and did not play the role of body diode protection. So the question is: where have I not set it yet, right? Or what should we pay attention to?