Other Parts Discussed in Thread: LMZ31520

I'm seeing my LM27402 circuit exhibit odd behavior at very cold temperatures. At -40C, the circuit comes up but is delivering significantly lower than the set voltage, usually around 2.8V for my 3.3V design.

Not shown, but we seem to periodically get into a state where the switch on time is very short, there are large hiccup gaps, and the voltage drops even lower, below 2V. This looks a reset of the controller of some sort, a bit like the way an overcurrent event is described, but we're at a very low current at this point in the system, and there's not a huge current inrush, as this regulator, my main 3.3V supply, is taking over part of the system from a linear pre-boot power supply.

As we get to around -22C, the regulator hits normal regulation and the unit comes up fine.

Another odd thing we found by accident. One of my guys had put a direct 50 ohm probe on the CS+ node... I didn't notice the type, given the test unit being in the temp chamber and all. With that probe attached to our scope, we stopped falling into the long hiccup/reset mode periodically.

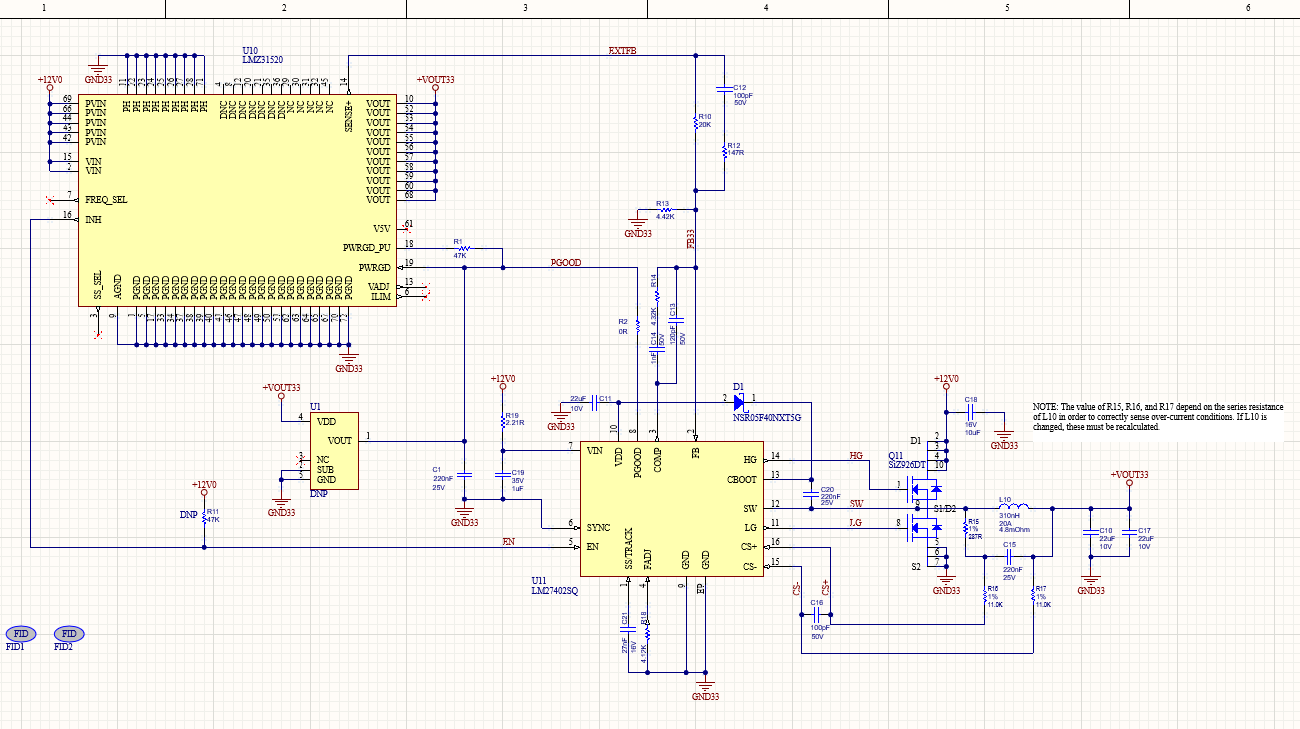

Here is the schematic. This is an LMZ31520 replacement module, so the LMZ31520 isn't an actual chip, and there is considerably more external capacitance surrounding this unit, as well as a completed feedback loop from the output via EXTFB on my main board.

So any suggestions at tweaking away this cold sensitivity are greatly appreciated.