Hi

For a solar charger solution, I am looking at 2 possible implementations;

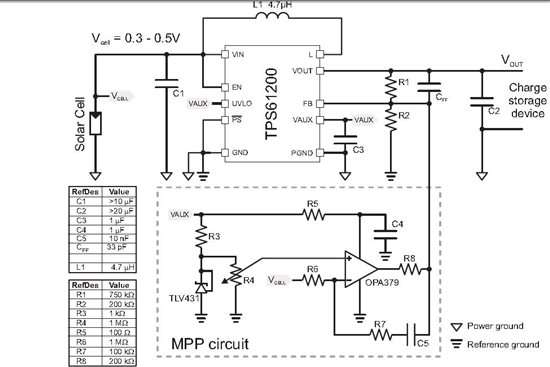

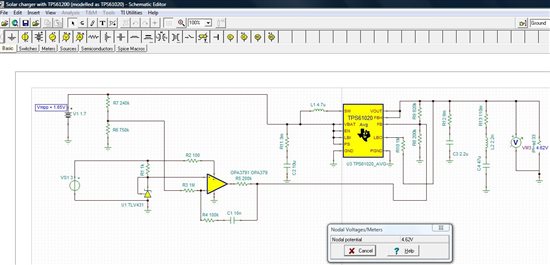

- previously discussed on this forum (and in app note slva345a), a design based on a 3 cell panel with TPS61200 + MPPT ---> bq24071 Li ion charger ----> TPS63010. The charger has a 3 cell PV panel with 1.5V vmpp and up to 500mA at Vmpp. The TPS61200 dc converts this and provides Vin for the bq24071 to charge a built in Li ion cell. The TPS63010 then dc converts the battery voltage to 5V.

- TI present a design in Nigel Smith's/Jinrong Qian's app note using bq24030 (slua394). I realise that I need a higher voltage panel to drive the bq24030. but I am considering prototyping and following the bq24030 with a dc conversion stage.

Which approach is more likely to be the 'best'? Criteria are electrical efficiency and BoM cost. I have EVMs for option 1 above.

Tks

Tony