Other Parts Discussed in Thread: TCA9617A, BQSTUDIO

Hi team,

Here's an issue from the customer may need your help:

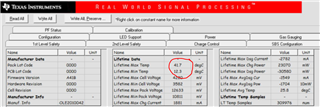

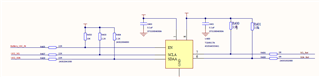

BQ20Z95 is used as battery gas gauge IC. IIC BUS as data interface.

Between MCU and battery, the customer use TAC9617A as IIC repeater.

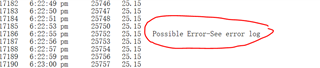

They monitor the temperature data of battery by MCU with IIC bus, it's found there are some extremely low(-273.05, -272.55) and high(317, 5380.85, 5329.45) temperature data during monitor process, although the rate less one in a thousand.

Whatever they change pullup resistor value, the extremely temperature always exist.

Could you help analyze why this issue happen and give a hardware solution? Thanks.

Best Regards,

Cherry