Other Parts Discussed in Thread: BQ34Z100-G1, BQSTUDIO, BQ34Z100, BQEVSW

Hello,

My target battery is 12V 35Ah PbA AGM Valve Regulated type and I'm using the BQ34Z110 most commonly used for PbA.

The 2013 data sheet and posts for PbA applications call for starting with a fully charged relaxed battery before IT Enable.

However, older and newer application reports, SLUA903-July 2018, and SLUA597-MAY2011 call for starting with a fully discharged relaxed battery before IT Enable.

Examples in these reports are for lithium chemistries, so I'm not clear if they apply to PbA.

(1) Can someone explain why for the PbA chemistry, status 5 is to be achieved on discharge, and for lithium chemistry it's on charging?

(2) Which learning cycle procedure is currently recommended for my battery?

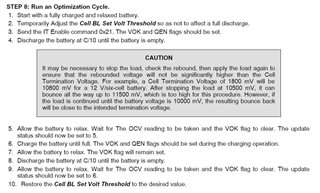

(3) Is the modification of the senc file usually required for batteries with high voltage rebound?

(4) After IT Enable 0x0021 is set prior to the first learning cycle attempt, does it need to be reset before starting subsequent attempts?

(5) When is RESET 0x0041 to be used?

(6) Will the learning process accept interference with the voltage rebound?

For instance, once the discharge load reaches the desired termination voltage and is removed,

can I reapply the load in bursts as needed to keep the rebound below the intended termination voltage to achieve the update status 5?

(7) One option to get past the voltage rebound issue is to increase the cell termination voltage and thereby increase the capacity reserve.

After learning is complete, could the BATLOW Alert thresholds be changed to indicate a SOC level below zero but within the reserve range?

This won't create a conflict with the gauging algorithm?

(8) Are these settings still recommended for PbA where voltage rebound is an issue?

Discharge =>C/8 to 1667mv/cell (10V for 6S)

Cell Termination Voltage=1800mV/cell (10.8V)

Cell BL Set Volt Threshold=1600mV/cell (9.6V)

FConvEn=0

I'm getting a voltage rebound of 1.35V which overshoots the 10.8V target by 0.55V.

Thank you.