Hello,

My customer is using 20-Pin HTSSOP package.

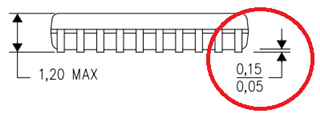

The drawing on page 47 of the data sheet shows a gap between the back of the package and the PCB.

To ensure that the rear thermal pads are soldered to the PCB land pattern, should the through holes on the PCB land pattern be filled with resin so that no soldering from the through holes flows to the back of the PCB?

Best regards,

K.Hirano

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.