Other Parts Discussed in Thread: BQSTUDIO, BQ34Z100

Hello,

How do I create a restore point for the device and bqSTUDIO prior to learning and how do I return back to this point if needed?

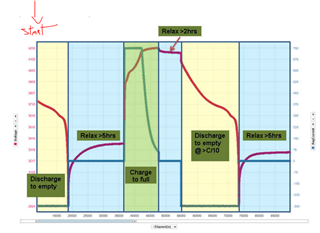

This thread is for LFP. What is different for PbA?

The thread also offers some advice for a good start on the learning cycle.

It refers to the TRM, presumably SLUUBW5A, after saying:

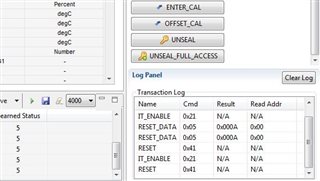

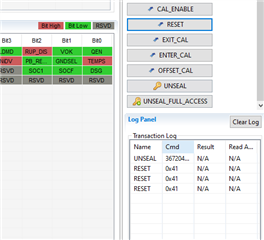

The basic idea for the first step is to get RUP_DIS = 1 without being able to toggle IT more than once, which isn't relevant to this gauge.

Yet the TRM never shows RUP_DIS=1.

bq34z100-G1 TRM sluubw5a 59.pdf

What corrections if any are needed?

Sincerely,

Rom