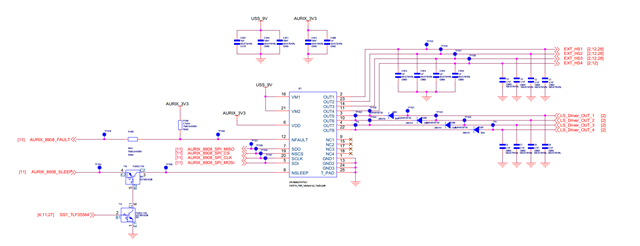

Other Parts Discussed in Thread: TEST2, , DRV8908-Q1

Hi TI engineer,

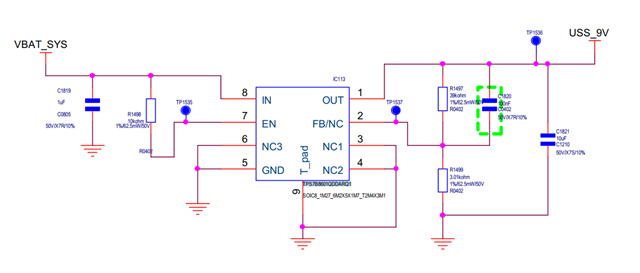

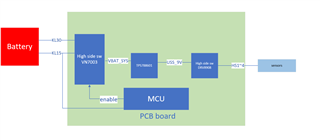

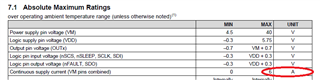

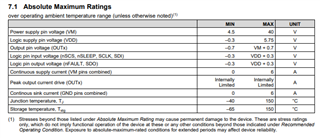

In our project the TPS7B8601QDDARQ1 is use for battery conversion to 9V ,and the voltage range of battery is 9~16V(normally 14V)

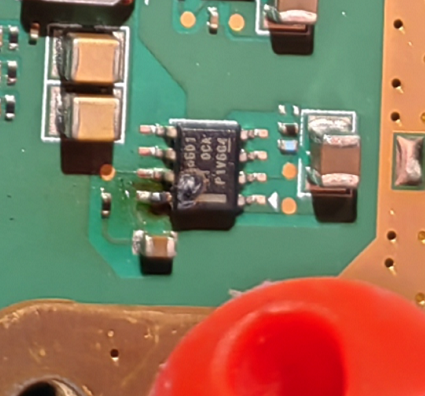

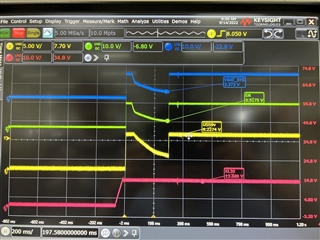

We found 2 PCB boards encountered TPS7B8601QDDARQ1 chip damage. Both the two broken PCB are 8PIN(Battery IN) damaged,The TPS7B8601QDDARQ1 has thermal shutdown and current limit function,but the power supply IN damaged,we want to know what can cause PIN8 damage?