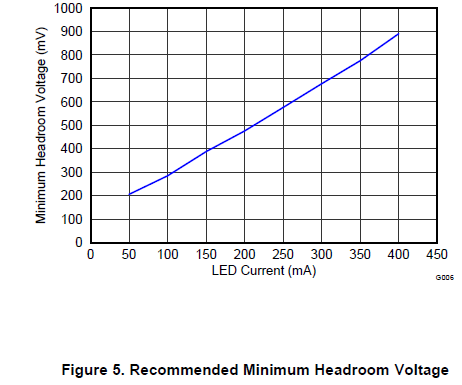

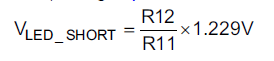

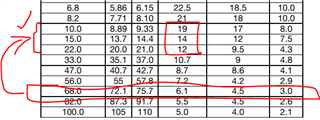

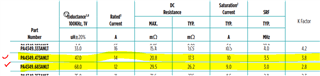

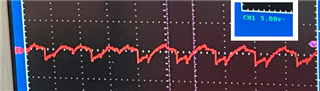

I need the 400mA design on my setup. I have changed R26 (ISET, 37.4K, 130mA) to 12.3K ( I believe it will make 400mA) based on ILED(400mA) =VISET(1.229)/R26(12300) x KISET(3992). Actually I fed 5% duty 60Hz PWM, and changed the R26 to different values, but it works up to around 280mA (R26 = 18K). I could not get a working condition either with R26 = 16K (it would be ILED = ~300mA). It works ok with R26 = 18K (it would be ILED = ~280mA). Please advise how to make the ILED = 400mA working condition on the TPS61196EVM-600 board?

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.