The TPS22916xx is an incredibly small, single channel load switch using a low leakage P-Channel MOSFET for minimum power loss available in a small, space saving 0.78 mm × 0.78 mm, 0.4-mm pitch, 0.5- mm height 4-pin Wafer-Chip-Scale (WCSP) package (YFP).

Because of this device's small package and fragility, any sort of rough handling conditions while being placed onto the board could cause damage that would cause unexpected functionality, therefore manufacturing and handling is going to be very critical for this device.

If you see unexpected performance or shorting from the input to the output, these issues are likely due to a soldering/ handling issue or a limitation with your PCB manufacturing process.

Foremost, we recommend to the manufacturer to reduce the nozzle pick and place force.

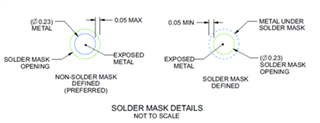

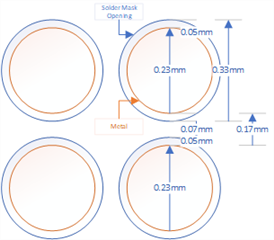

Another possibility is an issue with the solder mask opening: The solder mask width needs to be 0.07 mm; however, some PCB fabrication houses reduce the solder mask opening to create space for the solder mask strip. So ensure that they are capable of maintaining the 0.07mm solder mask width requirement. Also ensure that reflow profiles are specified for TI parts.

The packaging on this device is fragile, so small chips during the manufacturing process can cause a device to fail. Double check the soldering profile as well (common reason for failure on these devices is improper soldering).

In general, here are some resources in regard to WCSP handling:

https://training.ti.com/troubleshooting-tips-ic-wcsp-handling?keyMatch=WCSP

https://www.ti.com/support-quality/faqs/wafer-level-chip-scale-package-faqs.html