Other Parts Discussed in Thread: TPS54560,

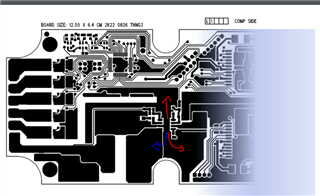

https://drive.google.com/file/d/1Wl4QeXNmdnPTEHqAqKZgJTs-wI_8RmnF/view?usp=sharing

Too much heat is generating over the board and the IC Temperature goes beyond 94.2 Degrees with normal load and 105 degrees with 70% switching load

Load Type : 72W LED

Result-1 :

Too much heat is generating over the board and the IC Temperature goes beyond 94.2 Degrees

Load Type : 72W LED Connected with MOSFET and 75% Dimming@ 14KHz PWM frequency

Result-2 :

1. Temperature further shoots up to 102.4 degrees

2. Humming sound is coming if we decrease MosFet Switching frequency below 12 KHz

Test Conditions:

1. IP67 based enclosure design , No Wind or Air Circulation for the IC cooling

2. Ambient Temperature of the LAB : 28 degrees

3. Readings are taken from Thermocouple ( Placed over the TPS54560 IC)

3. All reading are with Box Lid is closed

4. Used MosFET to drive the LED LOAD in Test condition-2

Requesting E-2-E Community to please advise on this, how to further reduce the heat generation