Other Parts Discussed in Thread: BQSTUDIO

Hello,

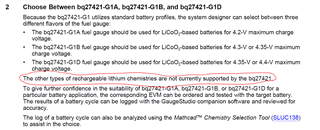

We regularly experience dips like this in our fuel gauge data. In the dataset attached, you can see StateOfCharge dips sharply around 12PM, by 9% in one sample, and it seems triggered by a corresponding drop in RemainingCapacity. I see no sharp change in temperature, but also, the load should not have changed here, so I'm unclear why the compensated value in RemainingCapacity diverges so much from NominalAvailableCapacity. We have SMOOTHEN enabled (we do not modify it from the default value).

Is this expected? Can you provide some guidance on how to debug further?