Other Parts Discussed in Thread: GPCCHEM, BQSTUDIO, , BQ78Z100, BQ28Z610,

Hi,

I have 2 Questions regarding battery training process, need expert's feedback for same.

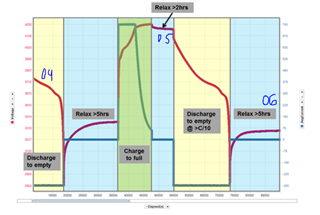

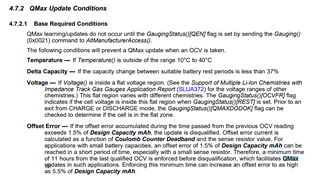

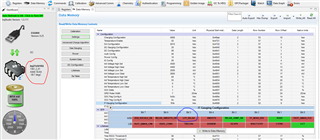

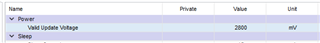

1) I found SLUA903 document to achieve successful learning cycle. The whole procedure is given in this document but i just want to know that do we have to follow all these steps simultaneously because whole procedure takes about 26-30 hours for full accuracy. I think it is impossible to sit these much hours continuously to complete the process.

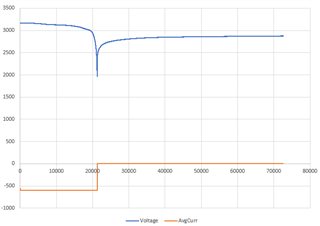

2) I found chem ID using GPCCHEM tool but it is showing Best chemical ID max. deviation, % : 11.41, so can i work with 11.41% deviation or not?

And also recommended best chem ID is matches to NiMH chemical but i am using LiFePO4 battery, so in this case can i use this chem ID or not?

I am attaching this report, please go through it.

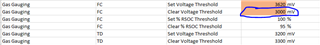

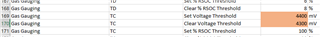

Chemistry ID selection tool, rev=2.53 Configuration used in present fit: ProcessingType=2 NumCellSeries=1 ElapsedTimeColumn=0 VoltageColumn=1 TemperatureColumn=2 CurrentColumn=3 Best chemical ID : 6106 Best chemical ID max. deviation, % : 11.41 Summary of all IDs with max. DOD deviation below 15% Chem ID max DOD error, % Max R deviation, ratio 6106 11.41 0.47 400 11.62 4.99 457 12.02 1.99 482 12.25 2.1 414 12.38 0.54 481 13.93 0.7 439 14.46 1.68 485 14.94 0.87 487 14.94 0.87 Max. deviations for best ID is within recommended range. Chosen best chemical ID is suitable for programming the gauge. Selection of best generic ID for ROM based devices like bq274xx Device / Family #1 Generic Chem ID Device/ Voltage/ Chemistry max DOD error, % 354 bq27411-G1C: 4.35V LiCoO2 32.72 3142 bq27421-G1D: 4.4V LiCoO2 38.08 128 bq27421-G1A: 4.2V LiCoO2 43.12 312 bq27421-G1B: 4.3V LiCoO2 97.48 Best generic ID 354 Warning: Generic ID Deviation is so high that it is most likely due to anomaly in the data. Please check that data files have recomended format, units and test schedule Device / Family #2 Generic Chem ID Device/ Voltage/ Chemistry max DOD error, % 354 bq27621: (ALT_CHEM2) 4.35V LiCoO2 32.72 1202 bq27621: (default) 4.2V LiCoO2 32.98 1210 bq27621: (ALT_CHEM1) 4.3V LiCoO2 36.35 Best generic ID 354 Warning: Generic ID Deviation is so high that it is most likely due to anomaly in the data. Please check that data files have recomended format, units and test schedule Device / Family #3 Generic Chem ID Device/ Voltage/ Chemistry max DOD error, % 3230 bq27426: (default) 4.35V LiCoO2 30.5 1202 bq27426: (ALT_CHEM1) 4.2V LiCoO2 32.98 3142 bq27426: (ALT-CHEM2) 4.4V LiCoO2 38.08 Best generic ID 3230 Warning: Generic ID Deviation is so high that it is most likely due to anomaly in the data. Please check that data files have recomended format, units and test schedule

Thanks,

Parth