Hi Team

At present, there are a few questions on the EVB of TPS92643, and I would like to ask for advice.

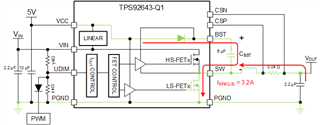

The environment we use is as follows (details are in the attached file)

1. Input 12V~16V

2. Output 2Pcs LED

3. IADJ adjusts LED output current 0.1~1.7V

4. Connect nExt_PWM to 30Hz, 1ms(low) signal

During the test, adjust the voltage of IADJ. When it is about 0.1V~0.6V, the LED current can increase in sequence and the operation is normal.

But when it is adjusted above 0.7V, the current output action does not keep up with the nExt_PWM signal. I don’t know why?

Excuse me,

1. To control the switch of the LED output current, is the nExt_PWM pin used?

2. Is there a program to calculate each parameter that you can share?