Hello,

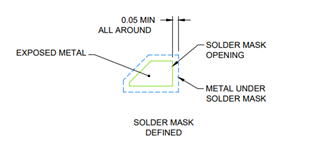

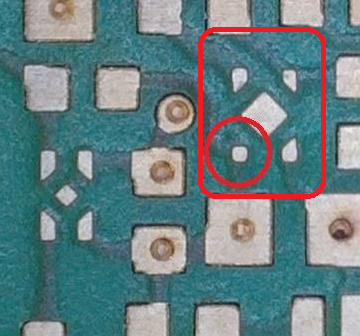

my supplier asked me to increase the solder mask opening to the size of the pad size.

https://www.ti.com/lit/ml/qfnd355c/qfnd355c.pdf

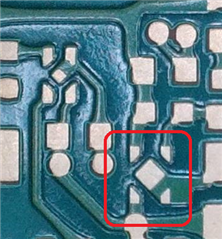

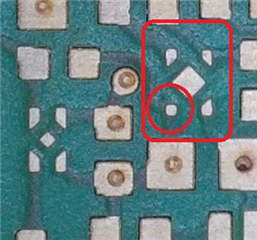

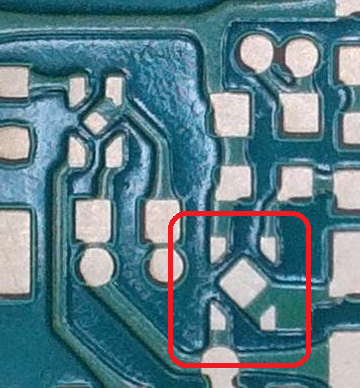

I created the footprint following our drawing of the DQN0004A.

Now the supplier has difficulties to create the small opening in the solder mask for pin 1 to 4. He is asking me to increase the solder mask to the pad size.

Does this greater opening of the solder mask influence solderability or there other mechanical concerns from your side?

Electrically it shouldn't have any influence.

Best regards,

David