We recently received a new batch of boards with a 24V buck converter that was failing production testing. The production test turns on a 4Ω resistive load, enables the 24V converter, and then tests the 24V rail.

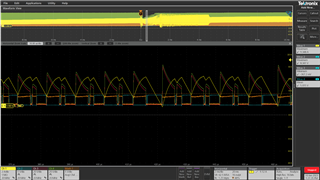

This converter uses the LM5116 with the specifications:

VIN: 36-85V

Vout: 24V

Iout(max): 8A

fsw: 200kHz

Tss: 50ms

High-side Switches: SIR632DP-T1-RE3

Low-side Switch: BSC077N12NS3 G

This converter has worked fine in the past (albeit, not optimally); however, these boards do have a component change. The converter schematic is shown below. D44 (NTS10120MFS), in parallel with the low-side synchronous switch, was changed to a new component with a slightly higher forward voltage drop: +0.2V (MBR15200DJF). Given this diode is not necessary, I am skeptical it is the cause of the problem.

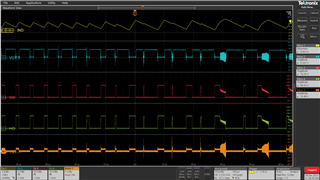

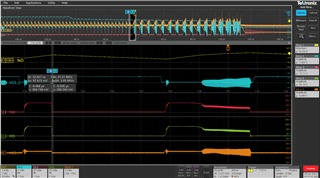

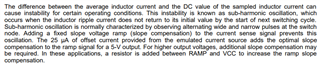

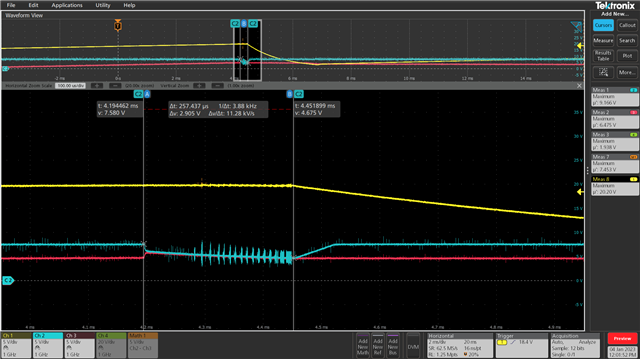

During testing, I found that the converter was hiccupping soon after the VCC voltage source was changed from the internal 7.4V LDO to VCCX. At this point, VCC drops down to ~5V, and then decays more slowly over the next few switching cycles to 4.7V. This was only experienced when starting under a load above ~4.5A. The next image shows VCC falling during a hiccup cycle. Yellow is Vout, blue is VCC, and red is VCCX.

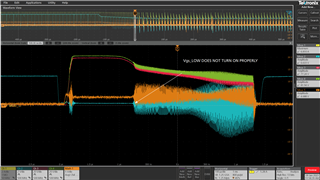

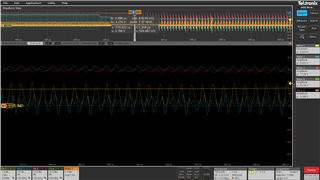

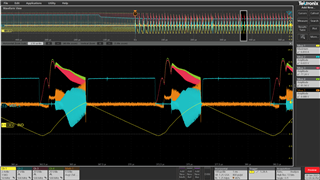

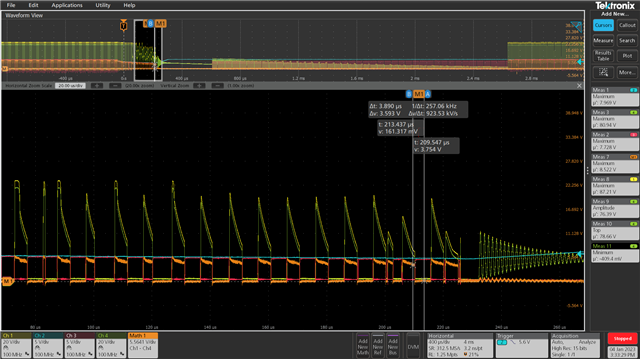

During this time, the Vgs of both low- and high-side switches also drop, causing poor enhancement of the FETs. In the image below, VCC is blue, high-side Vgs is orange, and the yellow and green signals are HO and SW, respectively. Please note, this poor turn-on is also seen on boards that start up under load and pass production testing. Furthermore, if a converter is able to ride out this period, VCCX increases, and the gates begin to operate normally. The margin between starting completely and not is clearly small.

I'm making this post slightly prematurely as I'm about to perform some more tests; however, it would be beneficial to have answers to the following questions:

1.) Would a different parallel low-side diode cause significant change to the switch node during this period that would explain why these boards do not function as well? I both removed the diode and replaced it with the old one and got the same result in each case. Does this then point to another change?

2.) If the switches are not turning on completely, what is actually causing the converter to turn off? We see large current spikes at this time (measured using the differential voltage of CS and CSG), but these are short in duration, and I don't think are likely to trip the OCP. Is the converter then just experiencing a VCC under-voltage fault?

3.) If we add additional capacitance on VCC/VCCX to allow VCC to remain higher for longer, will this allow the converter to get through the initial start-up?

4.) I calculated Igc as 14mA. If I were to ground VCCX and remove its function, would we experience excessive heating or poor performance? The datasheet recommends <15mA.

5.) Could tolerance stack-up in components (VCC/VCCX capacitors, bootstrap diode, LM5116 VCC undervoltage) just happen to be enough to impact the converter given its small VCC margin?

The design of this converter is being updated in a new revision of the board, but we have a stock of the current revision that we need to use. We have already noted a number of sub-optimal elements that will be addressed in the new design. What I am concerned with at this point is what is causing this latest batch of boards to not function correctly, when others did previously.

Any help would be welcome!