Other Parts Discussed in Thread: BQ40Z50, EV2400, BQSTUDIO

Hello,

I use a 4 cell configuration. I want to protect of under voltage cell (CUV) by opening FET automatically. Then below 2.9V of a cell (11.6V of stack for worst case), I want that FET switch off. Charger will wakeup system for charging.

I do not understand how to configure register for shutdown feature with PACK pin and configuration of charger present threshold register

I attached 5 picture to explain :

1) the PACK pin is connected to power bus that come from cell stack. Then power bus is not reserved for charger, it is the main line for stack cell too, Voltage can be 11.6V to 16.8V for example in normal operation

2) in state machine,

- switch from normal to shutdown is relative to "min cell voltage" and "charger presence treshold". These ones are registers, I find it in datasheet

- return from shutdown to normal is relative to "Vstartup", but I do not find any register

3) Conditions of switching mode are relative to PACK pin (see scheme upside), then I supposed to find registers that can be configured a few volts for 2,3 or 4 cells configuration (for me 4 cells)

4) the only "startup" word that I find in documentation is on HW datasheet and fixed to 2.25V. Then the 4 cell stack can never be under 2.25V (4 cells is about 8V..., lower is destructive). Then if it is the startup value used for switching mode, it always exit of shutdown because condition will be always true ! Then it is impossible (8V is > 2.25V !)

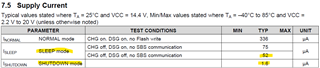

5) and for finish my mis-understood, the "charger present threshold" is set under 3V and it seems to have a contradiction

register seems to be cell-based and not stack-based

Then, I do not understand how to

- set vstartup for 4 cells

- set charger threshold for 4 cells

Thanks if you can help me.

Regards