Other Parts Discussed in Thread: GPCCHEM, BQSTUDIO

Hi:

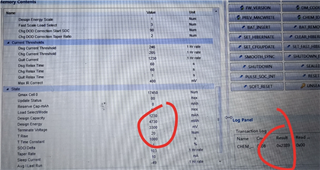

Information on the batteries used in our tests is as follows.

| Cell/Pack Info | |

| Cell/Pack Maker* | BYD |

| Cell/Pack Model* | LP113129 |

| Design Capacity* | 1230 |

| Charge Voltage* | Cell:4.40V |

| Cut Off Voltage* | 3.3V |

| Cell chemistry | Li-ion Battery |

The Fs file provided by TI after the golden learning has been loaded.

Problem Phenomenon.

During discharge, there is a problem of SOC jump, please help to confirm what is the cause?

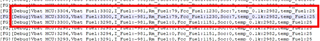

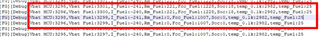

25℃ 0.2C discharge (12mAh per discharge, leave for 10 minutes), SOC 18% - 0%

1A discharge at 25°C (12mAh per discharge, 10 minutes standing), SOC 10% - 1%