Hello.

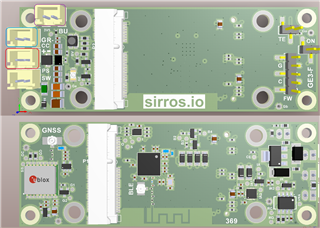

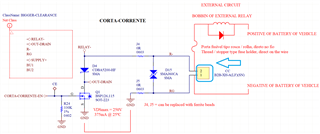

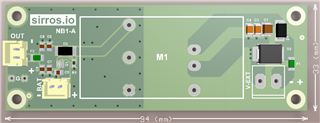

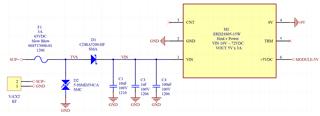

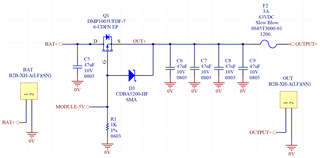

I have developed the design and layout of the PCB below, it is a power module PCB and it has 4 layers, and we have not produced prototypes of it yet. External supply is inserted at connector of right side, identified as V-EXT, the input supply voltage is from 10V to 60V, so it is compatible with 12/24/48V systems, the maximum is 60V because the breakdown(min) of the input TVS diode is 60V, it is rated for 5000W peak pulse power, but the power module identified as M1 actually can be supplied with up to 72V, so there is at least 12V off for input transients. The output of the power module M1 is 5V x 3A, and BAT connector is to connect a non rechargeable battery of LiSOCL2 type, 3.6V, 15Ah, high power type, which can supply peak currents of up to 3A. The power module M1 is isolated type (input-to-output), the manufacturer of it said to me that on it there is an internal high voltage capacitor of 1nF between pins GND and 0V. OUT is the output connector, two wires go from it to the application board that has an input power supply based on the buck-boost converter TPS63802.

Schematic below.

We want to redesign this board and make 2 modifications:

1. Add on the output of the PCB, on the left side, a Li-ion polymer/battery (3.7V/4.2V) charger IC (circuit), in which (A) the value of the charging current can be set through the value of a resistor, (B) that operates in switching mode and not linear mode, to obtain a good efficiency, and that (C) can deliver around 1A of charging current. Please note that here the input voltage of the charger circuit is the 5V that is the output of the power module M1. QUESTION: Which ICs of TI could be used for this?

2. On the external input supply of the PCB (connector on the right side) we wanted to also be able to connect solar panels and extract the maximum energy from them. I have no experience with solar panels until now, but I know a technique to achieve this is the MPPT. From Google: "An MPPT, or maximum power point tracker is an electronic DC to DC converter that optimizes the match between the solar array (PV panels), and the battery bank or utility grid. Also, about MPPT, I have never tried to study it deeply to understand how it works. Currently our company is working with the solar panels shown in the picture below, we are working only with this single model/size, but we will start using bigger solar panels which have double the capacity of supplying energy than this one. QUESTION: Which ICs of TI could be used for this?

Any suggestions or ideas?

Thanks in advance,

Jeferson Pehls.