Other Parts Discussed in Thread: EV2400, BQSTUDIO, BQ24230

We are currently using the BQ27421 in our product. The default design capacity is G1D = 3060. We are using a 450 mAHr battery in our product. If I read the STATE OF HEALTH, STATE OF CHARGE and REMAINING CAPACITY using the default, I get some numbers that look ok. they are not correct due to the difference in the Design Capacity value. If I change the Design Capacity to 450 from the default of 3060, the number look totally wrong. For example, I see the new design capacity number, but the

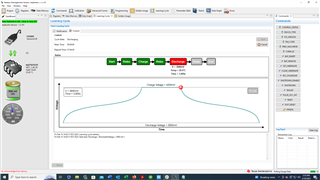

Here is the before:

Battery Voltage (mV) = 3855

Battery Current (mA) = 86

Battery Temp (C) = 22.65

State of Charge % = 42

State of Health % = 95

Design Capacity (mAH) = 3060

Remaining Capacity (mAH) = 1201

Full Charge Capacity (mAH) = 2877

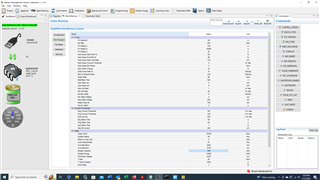

and here is the after

Battery Voltage (mV) = 3860

Battery Current (mA) = 86

Battery Temp (C) = 22.85

State of Charge % = 0

State of Health % = 95

Design Capacity (mAH) = 450

Remaining Capacity (mAH) = 0

Full Charge Capacity (mAH) = 0

Why am I getting bad readings?