Other Parts Discussed in Thread: GPCRA0, BQ34Z100-G1, , BQSTUDIO

Context:

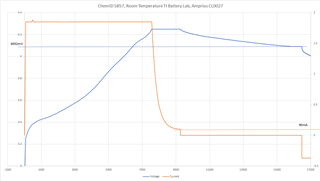

- Successfully finished the GPCRA0 process and the bq34z100-G1 is working great

- I know for certain that the CHEMID is correct because a new one was generated by TI specifically for these cells mid 2022

- These are interesting cells where they need 30psi of compression on them at all times in order to perform to the manufacturer's specifications. It was out of the scope to have TI do this for me during the characterization process at the cell level. The pack currently has a type of banding around it in order to achieve this. I understand that the cells will probably behave a little different than the original CHEMID now but it's the best we can do and IT is tracking very nicely after finishing GPCRA0.

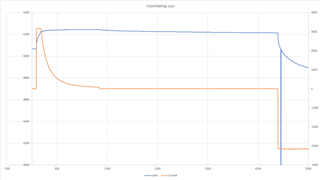

- C/2 discharge currents for both GPCRA0 and GPCRB

- GPCRB errors:

- Error: negative room temperature resistance observed R=-0.00992356722138726 usually caused by wrong chem ID selection

- Error: negative Ra R=-17.81 check data and ID selection

Thoughs/Questions:

- I'm not surprised it didn't go perfectly with the addition of the banding;

- What I'm really interested in is whether or not I can salvage anything from the GPCRB process;

- Can I still use the generated chemdat file or should I stay away from it?

- Can the negative RA just be fudged to something reasonable or will we have convergence issues with IT if I do that?

- Are the T Time Constant and T Rise values worth updating from GPCRB even if I don't use the generated chemdat file?