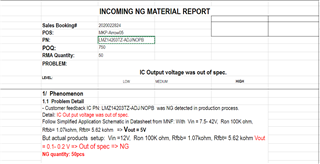

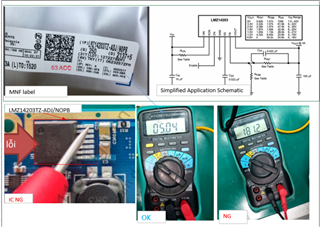

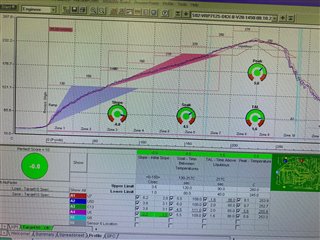

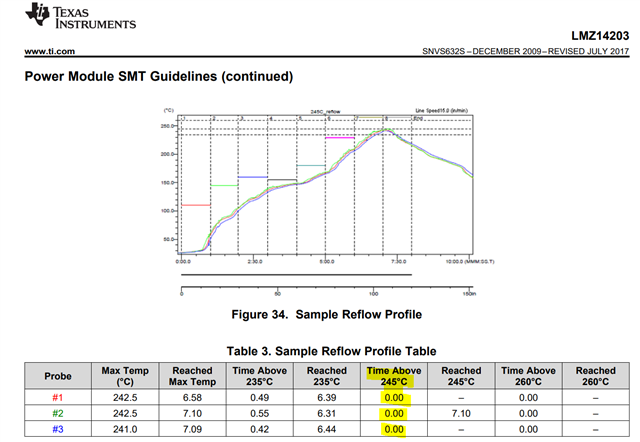

Dear Team, Have a nice day, We are using LMZ14203TZ-ADJ/NOPB part of TI but we are having the proplem as this above: Customer feedback IC PN: LMZ14203TZ-ADJ/NOPB was NG detected in production process. Detail: IC Out put voltage was out of spec. Follow Simplified Application Schematic in Datasheet from MNF: With Vin = 7.5- 42V, Ron 100K ohm, Rfbb= 1.07kohm, Rfbt= 5.62 kohm => Vout = 5V But actual products setup: Vin =12V, Ron 100K ohm, Rfbb= 1.07kohm, Rfbt= 5.62 kohm Vout = 0.1- 0.2 V => Out of spec => NG NG quantity: 50pcs Error and operation details are in the attached file. Please help us check this error. Please let us know if you have any information. Hope to hear from you soon.Thank you so much

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.