Hi,

I'm after a sanity check on an implementation. For no reason that I can see this chip sometimes fries to a dead-short.

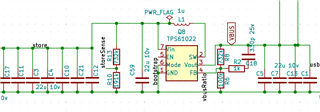

The design uses a large super-capacitor input (very low ESR) backed up by several 22u/10V/X5R/0805 capacitors. The voltage ranges from 0-5.23V. Due to the nature of the turn-on the chip will first turn on around the 1.7v mark and then can potentially continue to the lowest on level of 0.5V.

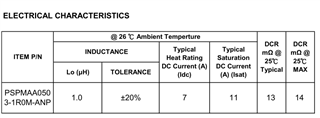

There is a 1uH inductor with a 11A/-30% saturation point.

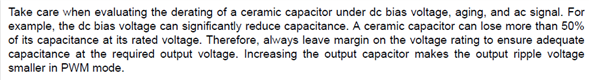

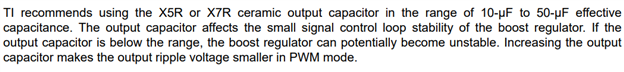

This feeds into 4x 22uF/10V/X5R/0805 capacitors.

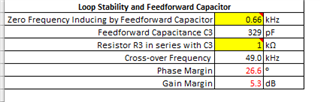

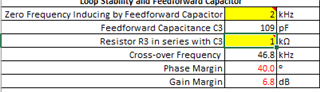

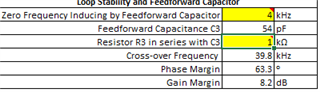

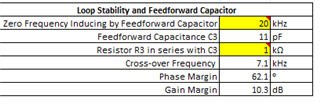

Due to a little overshoot on low current I added a 1k/330p feed-forward phase compensator. At very low current it regulates to 5.15v, then with any real load (>50mA) it regulates to 5V as expected. An oscilloscope inspection of the output showed it to be working correctly, clean (low) ripple.

The output is 5V and acts as VBUS. Technically the only current limiter is that of the TPS61022. There is a UVLO circuit on the VBUS line, if it detects less than 4.4V the VBUS output is shut-down. The UVLO is a hardware comparator driving an interrupt in a CPU so there will be a us duration delay, but it's still fast acting in the scheme of things. In the product that failed there definitely wasn't a short condition but I mention it anyhow.

The only other item of significance I have is that there was an excessive amount of heat generated which has to mean the super-capacitors were charged and then the short went through the TPS61022 at very high current. It was enough to melt the soldering on a connector! Since then VBUS is at very low resistance short, in the mOhm range

Regards,

Andrew