Other Parts Discussed in Thread: BQ27Z561, GPCRB, GAUGEPARCAL, BQSTUDIO, , BQ27Z561-R1

Hi Team,

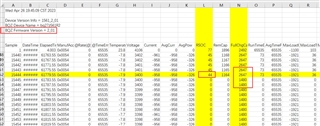

The customer developing a mobile phone battery pack with BQ27Z561. They tested the performance of low-temperature boot (-15°C). It was found that the RSOC jumped from 33% to 0%. The figure below is the voltage waveform (5s/div) of Pack+/-.

The following is the gg file, several key configurations are as follows:

NT02_1000mA_20230328ú¿├╪├▄ú⌐.gg.csv

From the waveform, the time when the voltage is lower than 3300mV lasts for about 2s, which is less than Term V Hold Time=4s. Why does RSOC become 0? Should Term Voltage+Term Voltage Delta=3.5V be the threshold? Could you pls help?

Regards,

HL